RollPros is trusted by:

The cannabis industry’s only automated pre-roll machine that rolls joints.

The Blackbird

Automated Joint Rolling Machine

The Blackbird’s unique, patented technology empowers our partners to produce high-quality, differentiated products that accelerate business growth and profitability. Imagine producing 5000 joints per shift at a fraction of your current cost with a machine that can fit through a standard doorway.

Find out why brands across North America are switching to the Blackbird.

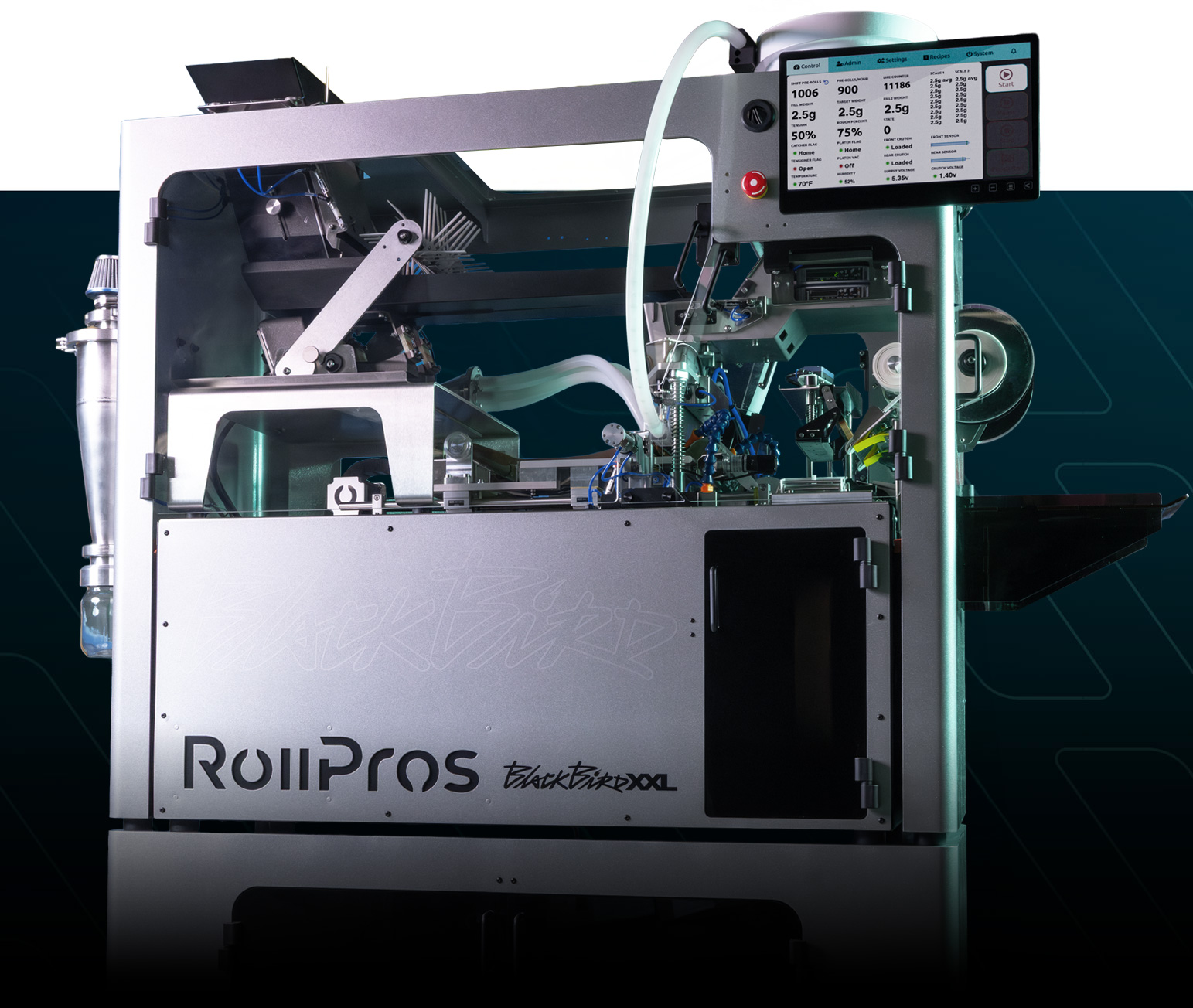

The Blackbird XXL

Automated Blunt Rolling Machine

The first automated machine built specifically for blunts. Designed for bigger wraps, bigger output, and bigger possibilities, the XXL brings the same trusted technology of the original Blackbird, scaled up for blunt production.

Find out what makes the Blackbird XXL the choice for serious blunt makers.

million joints (and counting) have been produced on Blackbird units.

Beyond customer service.

No problem. Check out our on-demand demo anytime. Watch now.

We believe in the spirit of partnership! Your success is our success, and it underpins everything we do at RollPros. We celebrate your wins with you, and help you through bumps and pivots when they come. Regardless of where your business is now, we are always there when you need help.

Made in the USA

No problem. Check out our on-demand demo anytime. Watch now.

At RollPros, we keep it simple: Our machines are made in the USA, and that’s never changing.

We don’t just claim to be a U.S. manufacturer, we actually are. Every Blackbird pre-roll machine is built at headquarters, just a few miles from where we source our parts and materials, ensuring consistent quality and reliable supply.

We believe in doing things the right way—supporting local suppliers, creating American jobs, and maintaining complete control over our production process.

No overseas outsourcing. No cutting corners. No compromises.

Design your perfect joint—start to finish.

Our interactive JointBuilder makes it easy to create custom pre-rolls that match your brand’s style and specs. Choose everything from paper type to crutch material, upload your logo, and watch your joint come to life in real time.

Want to see what your dream joint looks like?

Better than blogs.

RollPros publishes well-researched, thoughtful articles that help your business succeed in the pre-roll category.

The Joint Journal — January 2026: Key Updates, Insights & What’s Next

Pre-roll Challenge – Cones Vs. Straight Roll

RollPros Named to the 2025 Inc. 5000 List of Fastest-Growing Private Companies in America

Loading...

End of content

No more pages to load

SEE THE BLACKBIRD IN ACTION

Cones vs Straight-Rolled Joints: What Do Real Consumers Prefer?