Before diving into the math of it all, you first need to figure out the less tangible thresholds that must be met—what does your brand stand for, and what does your customer shop for? Consider things like:

6 Criteria To Consider When Choosing the Best Pre-roll Machine for Your Business

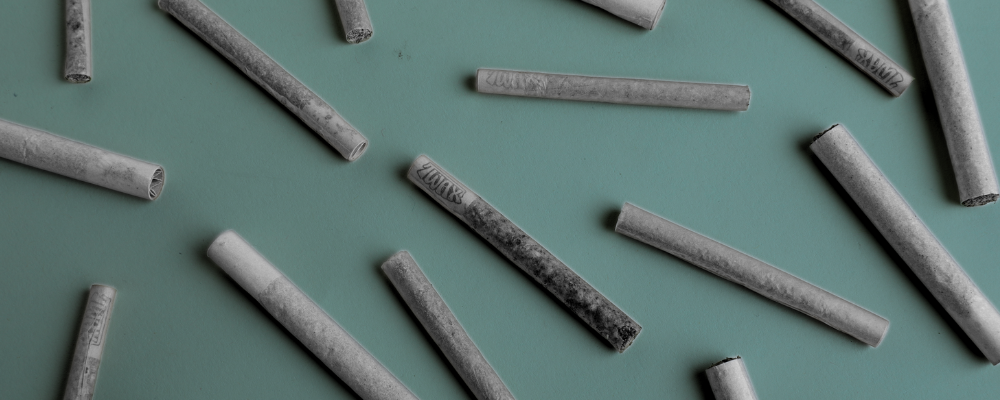

Pre-rolls are one of the most lucrative cannabis market segments in the country.

They’re popular, and they’re profitable. So picking the best automatic pre-roll machine for your business is a big decision.

We’ve done the stressful thinking for you and narrowed down the top six criteria to keep in mind when it comes to choosing the best pre-roll machine for your business.

1. Company Values + Customer Values

Does your brand cater to customers who shop the bottom shelf or the top shelf?

There are plenty of pre-roll machines out there that can create a fast, cheap commodity for shoppers who prioritize cost over function. Consider the price point you’ll be selling your pre-rolls at and the customer you’ll be targeting before investing in a pre-roll machine.

Is your target audience an experienced crowd who’s been smoking for years or a new, curious crowd still learning how to be discerning with their weed purchases?

If you’re focusing on seasoned cannabis consumers who may be more particular than newer consumers, you may want to avoid the pre-roll machines designed to create a quick, cheap product. Experienced consumers know a good joint; many know how to roll a good joint themselves. They’ll be able to tell if what you’re selling is not up to par.

Does your brand boast eco-friendly practices? On that note, do your customers prioritize buying eco-friendly products?

If operating an eco-friendly business is something you and/or your customers value, be sure to research the construction of your machine and its replacement parts. If your pre-roll assembly requires machines and parts to be shipped across the planet, your brand’s carbon footprint just went way up.

There are a lot of pre-roll machines on the market. Whichever one you pick will dictate your customers’ experience with and perception of your brand. Make sure it’s all in alignment.

2. Necessary Output Volume

You need to know how many pre-rolls your pre-roll machine must produce in order to meet your sales numbers, and you should also consider how much it would need to produce to exceed your sales numbers. (Seriously, pre-rolls are posting gains even in declining markets.)

There are a couple factors to hit here. Start with how many pre-rolls you’d need in one month, and work backward. How many is that per week? And how many is that per shift?

It’s the per-shift number you’ll want to focus on, as this is how the machine will operate.

Cost and ROI: Investing in the Best Pre-Roll Machine

Alright, let’s get down to the dollars and cents. Investing in a pre-roll machine is all about how much value it brings in the medium-to-long term. Sure, it might feel like a big chunk of change at first, so think hard about the savings on labor costs, the boost in production speed, material costs, and the consistency you’ll need. Flower should be your most expensive material input, but don’t forget the price of paper, tips, and packaging! All these considerations can add up – or lead to a quicker return on your investment. Find that sweet spot where quality meets efficiency, and your bottom will look better for it. Downtime is the boogeyman of automation, so quality customer service for your machine is a must have.

3. Facility Setup

Generally, automatic pre-roll machines are not that large and don’t require facility changes or adjustments. They still take up space, though, and some require a clear area around them for safety and maintenance. Make sure to check the dimensions and requirements of the pre-roll machine(s) you’re considering to confirm you have ample space for them to operate properly.

Keep in mind your necessary output volume as well. Will your operation require more than one pre-roll machine in order to hit that volume? Do you have room for more than one pre-roll machine?

Durability and Maintenance of a Cannabis Pre-Roll Machine

Nobody wants a pre-roll machine that’s going to flake out after a few months. When you’re investing in any equipment, you want something that’s built to last. Pro tip: do a quick scan of where and how it’s being put together. High-quality materials and solid construction mean fewer headaches down the road. But even the toughest machines need a little TLC. Easy maintenance is key here; the simpler it is to clean and service, the more you can keep things running smoothly without wasting precious time. And when parts are easy to get to and replace domestically, it’s like a bonus. We’ve seen how frequently supply chains are thrown out of order through COVID-19 shutdowns or the more recent Baltimore bridge incident, so waiting for a part to come in from overseas has the potential to shut down your production for months, if not for good.

4. Reputation of Support

Get on a call with a physical person and get a sense of the support that would (or maybe would not) be available to you if you chose to buy. Be curious about their onboarding and training processes. Ask questions about the data the machine collects and how much access you have to it.

Learn about the relationship you would have if you bought that pre-roll machine. You do not want to have to switch pre-roll machines over a lack of support.

5. Replacement Parts + Consumable Materials

While you’re chatting with that sales rep, ask them about replacement parts for the machine as well as the consumables it will require, like paper bobbins or pre-rolled paper cones, filters, crutches, etc. Get answers to questions like:

-

-

-

- Are all the replacement parts coming from China? Meaning, are you dependent upon a long and fragile supply chain?

- What about the paper products? Where do they come from, and how are they made?

How often are replacement parts generally needed? What is the process to get them?

-

-

These parts and materials are crucial to any pre-roll machine’s function. Too many hurdles to get them and your operations could be impacted.

Customization Capabilities in a Pre-Roll Machine

The pre-roll market is crowded, but that’s where a machine with customization options can really make your product line stand out. In addition to the paper and crutch of your pre-rolls, imagine being able to tweak the size, shape, and even the density of your joints. Whether you’re catering to seasoned cannabis connoisseurs or the casual first-timer, having the ability to change your product quickly helps capitalize on demand. It’s not just about aesthetics, customization allows your business to meet specific market demands and provide a consistent, quality experience every time.

6. Company Endorsements

Check out the pre-roll machine’s website to see what companies are currently using the machine. Many websites will feature a banner on their homepage showcasing the logos of the companies they work with. There may also be case studies available on the site that are worth exploring.

We recommend taking it one step further by getting in contact with those companies directly to get their honest feedback about the machine and the support system behind it. Case studies are helpful, but a candid conversation can provide much more insight.

Conclusion: Making the Right Choice for Your Cannabis Pre-Roll Machine

From making sure you can customize every joint to keeping maintenance a breeze, each factor plays a big role in how your business will perform. The right pre-roll machine can make all the difference in helping you stay ahead of a crowded market. So, take your time, weigh your options, and make a choice that’s going to keep your brand rolling strong.

If you went through this blog and thought things like…

“My customer does prioritize buying eco-friendly products.”

“My audience does shop the top shelf.”

“Customer support is really important to me and my team.”

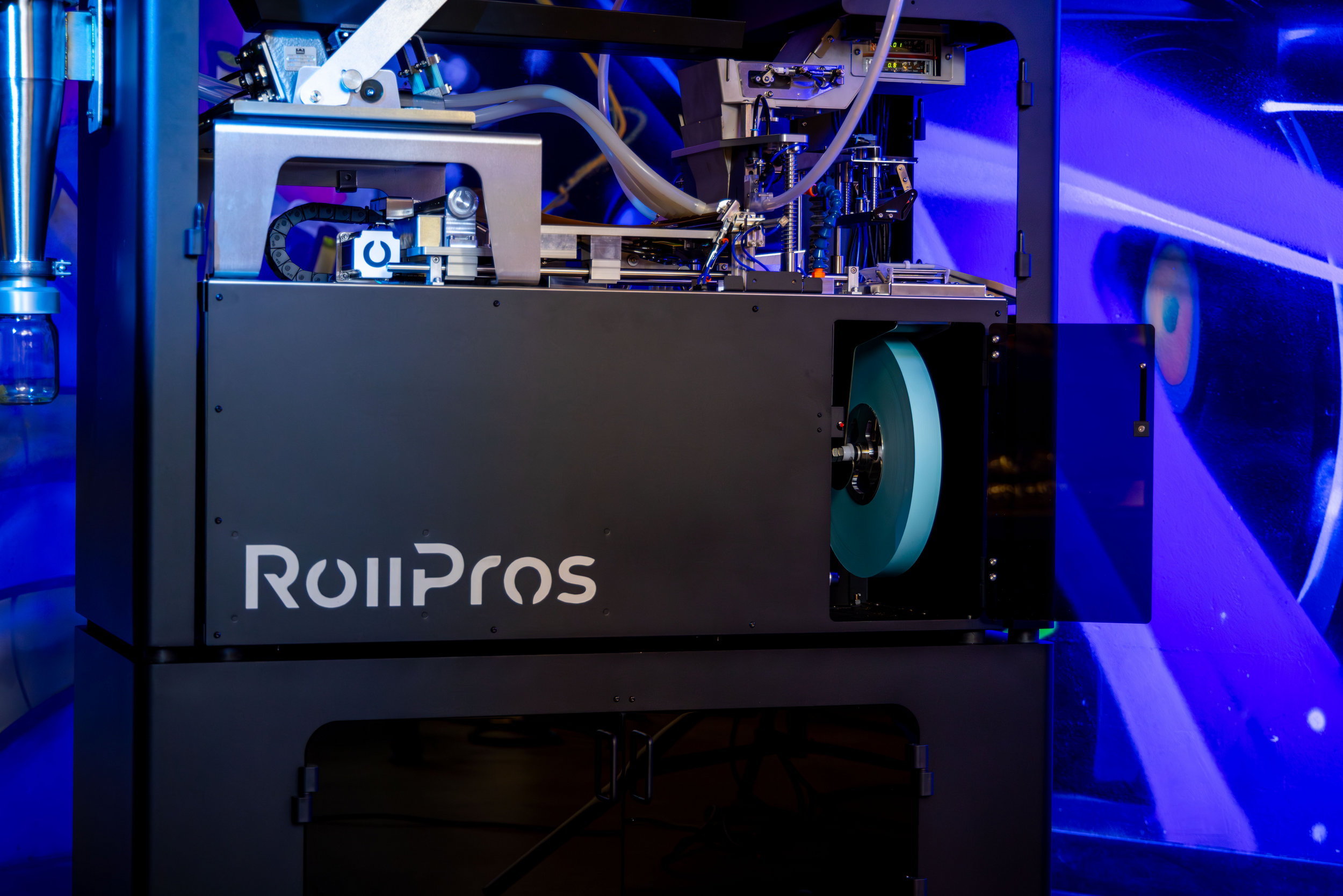

…good news—you’ve found the best pre-roll machine for your business. Say hello to The BlackBird.

This automatic pre-roll machine is unlike any other you’ll find in your research. Those are all cone-stuffing machines, and cones are technically not pre-rolls (if you ask us). The BlackBird is the only pre-roll machine on the market that rolls pre-rolls. And it does so at an average rate of 750/hour, though we have clients who’ve beaten that number by a wide margin.

The machine is manufactured in the USA, as are its consumable materials, so we can get you replacement parts and fresh rolling paper in no time without all the carbon emissions that come with cross-planet shipping.

If you’re looking to create a quality product that attracts a loyal following, you’re looking for the BlackBird pre-roll machine. (Just ask our current clients.)