In the pre-roll world, efficiency rules. Not sure how many times we’ve said it, but a streamlined workflow slashes costs, maintains quality, and speeds up production. For any brand looking to stay competitive, a tight process is a must-have.

Streamlining Pre-Roll Production for Maximum Efficiency

Why Efficient Pre-Roll Production Matters

Production slowdowns cost money, plain and simple. An optimized workflow boosts output, lowers labor costs, and cuts down on errors. With fewer mistakes, you’re wasting less material, and quality stays consistently high. In a fast-paced (and growing) industry, a well-oiled process gives you a serious edge.

Driving Production with Workflow Automation

How Workflow Automation Powers Efficiency

Just imagine what a car factory floor looked like 50 years ago compared to today. What’s arguably the biggest difference? Workflow automation. It takes care of the repetitive, time-draining tasks, letting your team focus on what really matters: quality. In pre-roll production, automation has the potential to handle weighing, rolling, and packing, keeping operations fast and accurate from start to finish.

Workflow Automation Benefits in Pre-Roll Production

- Consistent Output: Automation keeps production flowing smoothly.

- Reduced Error Rates: Fewer hands in the process means fewer mistakes, leading to a more consistent, higher-quality product.

- Time and Cost Efficiency: Routine tasks get streamlined, cutting labor costs and freeing up your team for higher-value work.

Key Steps to Optimizing Pre-Roll Workflow

Start strong. Automated inventory checks, task assignments, and scheduling software help pre-production run like clockwork, setting up a smooth process from the start.

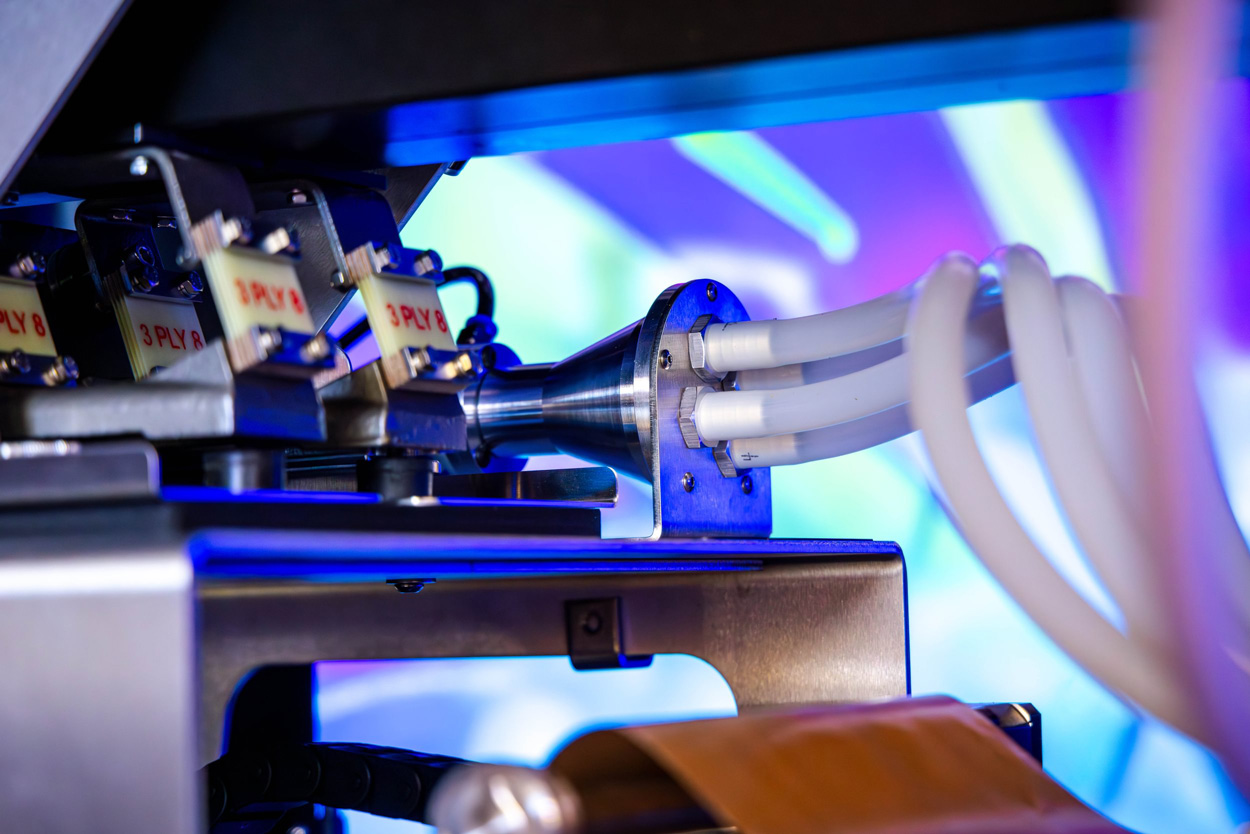

During production, pre-roll machines handle the heavy lifting of weighing, rolling, and packing. With precise automation, these machines deliver consistent density, reliable potency, and even burns in every joint, taking the hassle out of hand-rolling. If you’re interested in the differences in the pre-roll systems themselves, take a peep at our detailed list.

Quality control is critical. Automated tools, either built into your machine, pre, or post production are important. Consider checking each joint’s weight, density, and draw, ensuring everything meets your standards (or regulatory requirements). There are plenty of tools that reduce manual checks, making quality control faster, easier, and more accurate.

- Pre-Production Automation

-

Start strong. Automated inventory checks, task assignments, and scheduling software help pre-production run like clockwork, setting up a smooth process from the start.

- Using Pre-Roll Machines for Production

-

During production, pre-roll machines handle the heavy lifting of weighing, rolling, and packing. With precise automation, these machines deliver consistent density, reliable potency, and even burns in every joint, taking the hassle out of hand-rolling. If you’re interested in the differences in the pre-roll systems themselves, take a peep at our detailed list.

- Automated Quality Control

-

Quality control is critical. Automated tools, either built into your machine, pre, or post production are important. Consider checking each joint’s weight, density, and draw, ensuring everything meets your standards (or regulatory requirements). There are plenty of tools that reduce manual checks, making quality control faster, easier, and more accurate.

Must-Have Workflow Automation Tools for Pre-Roll Production

Top Automation Tools for Production

- Integrated Pre-Roll Machines: All-in-one machines streamline production by handling weighing, rolling, and if necessary, finishing/twisting—delivering joints in less time.

- Automated Packaging Solutions: Automated sealers and labelers get your product retail-ready fast, eliminating bottlenecks in the final stages.

Task Management for Team Alignment

- Project Management Software: Platforms like Asana and Trello keep your team on the same page, making sure tasks move forward without a hitch.

- Automated Video and Marketing Content: Brands with heavy content schedules can rely on automated video editing tools to keep things consistent and looking professional.

Solving Production Challenges with Workflow Solutions

Avoiding Workflow Bottlenecks

Bottlenecks can grind production to a halt. Real-time workflow tools monitor output, alerting your team to any slowdowns, so everything stays on track.

Scaling Workflow Solutions for Growth

As demand grows, scalable automation tools help production keep up without sacrificing quality. Flexible workflow solutions maintain consistency, no matter the volume.

Measuring Success and Optimizing Workflow

Tracking Workflow Performance

Metrics like production speed, cost per joint, error rates, and downtime show where your workflow shines and where there’s room for improvement. Regularly checking these KPIs keeps things efficient.

Updating Workflow Automation Tools

Production needs change over time. Updating automation tools as demand increases or new tech emerges helps you stay ready for anything.

Conclusion: Dominate Pre-Roll Production with Seamless Workflow

An optimized, automated workflow boosts production, lowers costs, and ensures high quality. With smart workflow solutions in place, you’re set to meet demand and deliver reliably excellent products, giving your brand the edge it needs to thrive.