As pre-roll aficionados, we’re not against the occasional “alley test.” But, as business owners, we also think it’s important to consider what’s lost every time employees step out back for a little quality control.

(Draw)Check Yourself Before You Wreck Yourself

Here’s How To Guarantee Product Consistency

Whether or Not You Roll With the Blackbird

Whether or Not You Roll With the Blackbird

(But You Should Definitely Also Roll With the Blackbird)

-

- Money is lost on the physical product that’s being freely inhaled and is no longer sellable (not just the flower, but the paper and filter too)

- Money is lost on the time the employee(s) spent away from their work

- Money is lost on the wear and tear put on the pre-roll machine to create a pre-roll that was never sold

- Money is lost on the utilities used to power the pre-roll machine that made the pre-roll that was never sold

Some of the above points might seem trivial, but as we’re sure you know, there’s really no room in the cannabis industry to waste money. Plus, these losses happen every time someone steps out back to test the product. If that’s multiple times a day, or even a week, the cost is going to add up quickly.

Of course, to make money, your pre-rolls need to pull well, and they need to do so consistently. So we created DrawCheck—the industry’s only machine that will gauge the draw of your pre-roll. With DrawCheck, you can guarantee a consistent hit from batch to batch and facility to facility without having to burn a few down in the process.

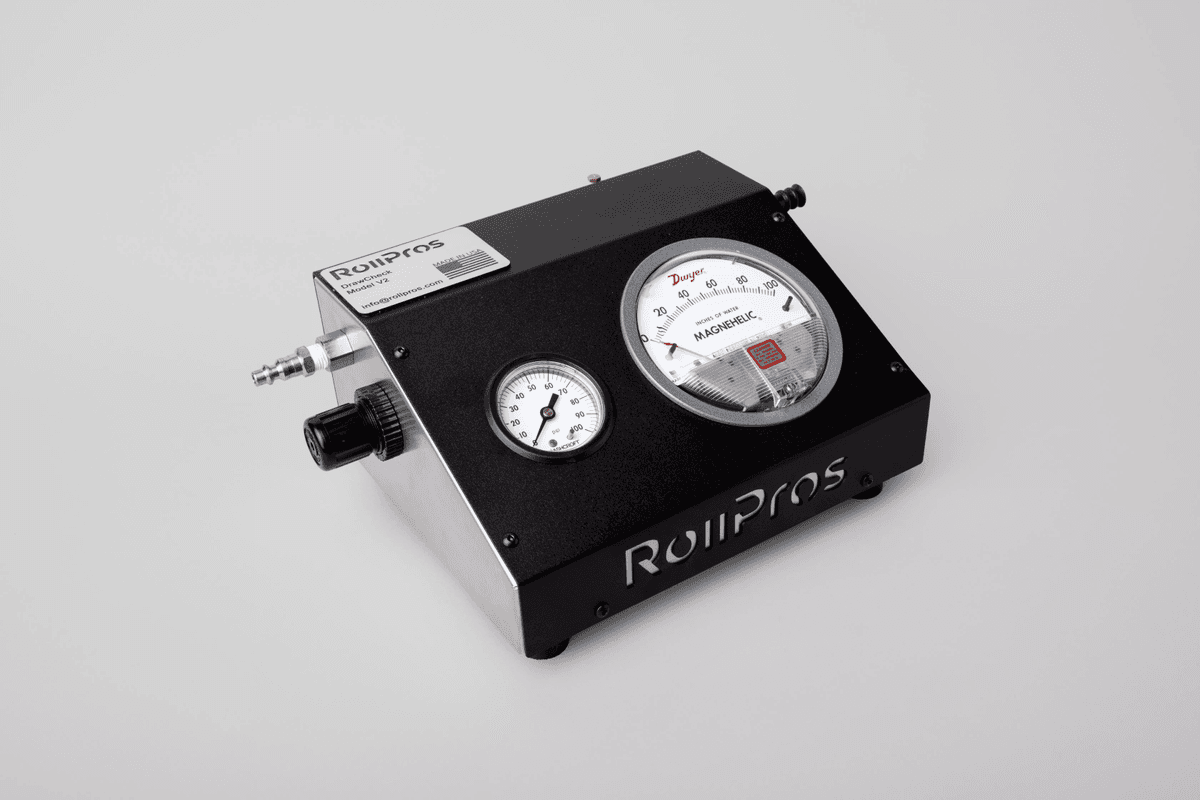

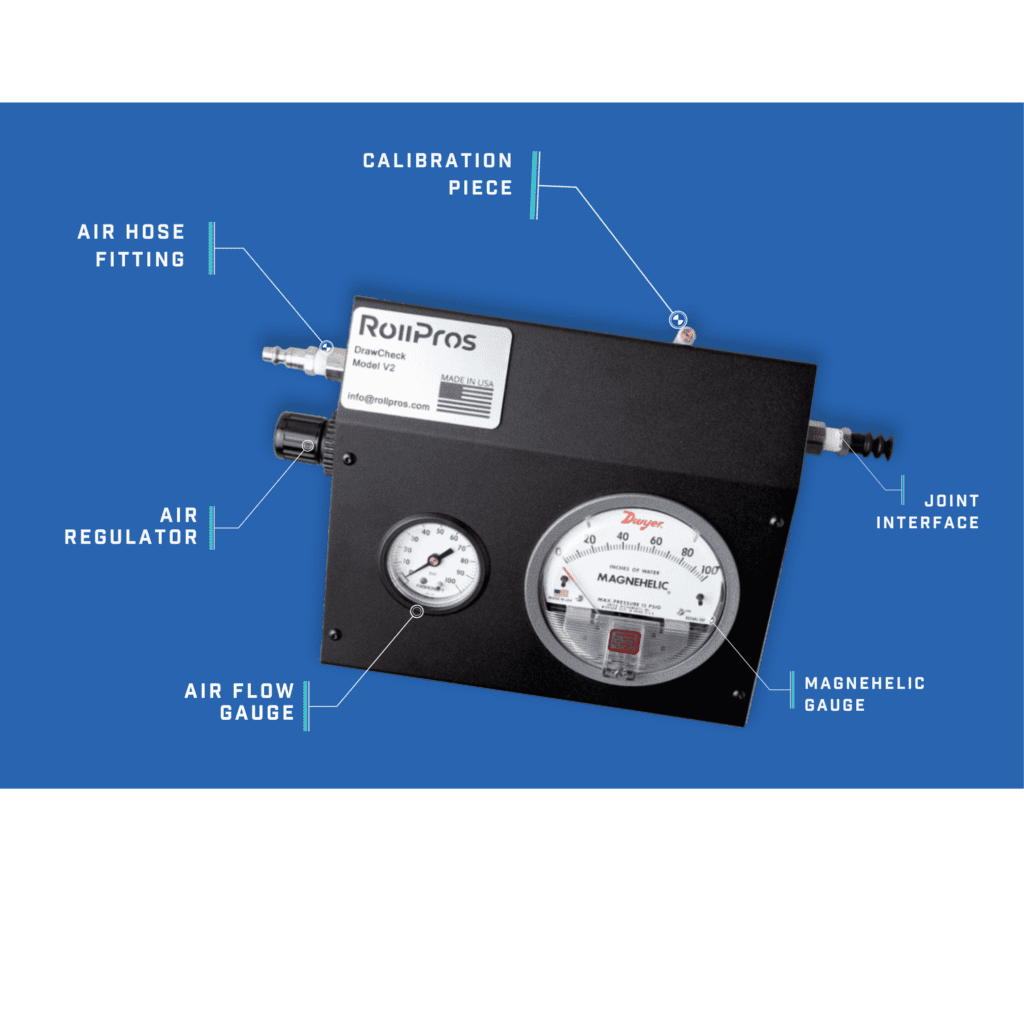

Meet RollPros DrawCheck

DrawCheck is a desktop machine that requires no AC power; all you need is airflow. That means you won’t need to increase your utilities budget or adjust your floor plan to incorporate it into your SOPs.

In 3 easy steps, you can determine if you need to adjust your flower grind, your flower amount, or the tension of your pre-roll in order to achieve maximum airflow with every pre-roll.

How DrawCheck Works

-

-

- Hook it up to air

- Adjust the airflow to calibrate the machine

- Place your pre-roll on the suction end

-

The machine reads similarly to a tire gauge. If the gauge lands higher than 30, your pre-roll is packed too tightly and is hard to hit. Consider a coarser grind of your flower, or if you’re rolling with the Blackbird, lower the tension. If it lands lower than 30, it’s too loose. Perhaps you need a finer grind or higher rolling tension. 30 is your sweet spot.

Because you can determine quality and consistency with a quantifiable metric, you can guarantee an even pack, an even pull, and an even burn across flower stains, pre-roll batches, and manufacturing facilities.

Download the DrawCheck spec sheet here.

Consistency Is Key to a Successful Pre-Roll Line

Cannabis is a cut-throat industry, especially in the pre-roll category. (Keep in mind, the competitive pressure we feel now is before interstate commerce—imagine the competition that will bring.) You must have a consistent product to succeed in this industry because there are too many brands out there for your customers to ever need to give your brand a second chance if it provides a subpar experience. This is a single-elimination game.

Our latest market reports explore the realities behind succeeding in the pre-roll category, and it comes down to one thing: consistency. If your pre-rolls aren’t consistent from purchase to purchase, your customers aren’t going to be either.

The DrawCheck enables you to provide a consistent pre-roll experience without having to waste any product in the process. When combined with the RollPros Blackbird, success is inevitable.

Check Out the DrawCheck

Curious to know how well your pre-rolls are currently pulling? Ready to take your product line to the next level? Our team is happy to walk you through a live demo of DrawCheck and work with you to determine if it’s the right product for your needs. Get in touch with RollPros today.