Let’s be real, efficiency isn’t just about saving a few bucks. It can make or break businesses. If you’re rolling pre-rolls, every minute wasted means money out the door. Whether you’re cranking out hundreds or thousands of joints, dialing in your operation means finding ways to cut costs, save time, and still deliver the quality that keeps customers coming back. Here’s how automation and smarter workflows can help you get there.

Transforming Cannabis Production Efficiency with RollPros Pre Roll Machines

1. Automation That Does the Heavy Lifting

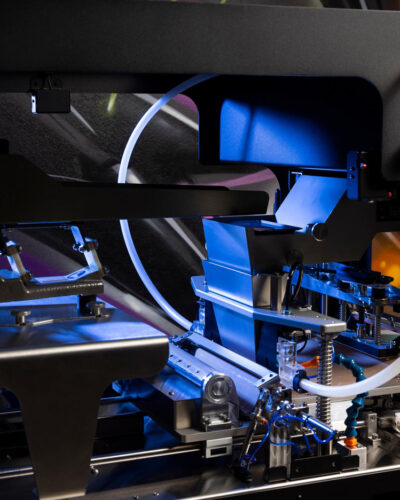

Pre roll production doesn’t have to be a grind (pun intended). With automated machines like RollPros’ Blackbird, you’re not just speeding things up, you’re turning a tedious task into a well-oiled machine (literally).

And let’s be honest: automation isn’t just faster, it’s often better. No more human error, no more inconsistencies. You’re rolling like a pro, but with a machine doing the heavy lifting. Think about it like this:

- Faster output: Pump out more pre-rolls in less time.

- Consistent quality: Every joint smokes like the one before it. No duds, no complaints.

- Less manual labor: Your team isn’t stuck doing mindless work, they’re focused on quality control and getting creative.

2. Less Labor, More Focus on Quality

Face it, repetitive tasks are boring. Labor is expensive, and in the cannabis industry, it’s a killer if not managed well. Automating the repetitive stuff gives your crew more time to do the real work that matters. Imagine what your team could achieve if they weren’t plopped in front of a finishing table or stuffing cones all day.

What happens when you automate labor-heavy tasks?

- Fewer mistakes: Humans get tired. Machines don’t.

- More time for innovation: Your team can focus on developing new products or improving existing ones.

- Consistent output: No more half-packed joints or lopsided rolls. Each pre-roll hits the mark.

Key strategies to maximize labor efficiency:

- Cross-train your team: When employees can step into multiple roles, you eliminate downtime and keep production moving even if someone is out or overwhelmed.

- Reduce repetitive tasks: Invest in small automations or tools that take the grind out of repetitive tasks—like weighing, cutting, or packaging—so your team can focus on higher-value work.

- Monitor productivity: Track the amount of time it takes to complete different stages of production and identify areas where you can trim down wasted time.

Your people are your most valuable asset, and how you use their time matters. Overworking your team leads to mistakes, burnout, and ultimately, lower productivity. Instead, focus on labor efficiency by making sure your employees are doing the right tasks at the right time.

3. Optimize Your Entire Process—Beyond Just Machines

Sure, automation helps, but efficiency is about more than shiny new machines. Every step of your production process has room for improvement. For example, knowledge of your material and moisture control. A dry pre-roll is a customer complaint waiting to happen, and nobody wants that. By using moisture content readers and/or proper curing methods, you make sure your product stays fresh and smokes smoothly. Also, a DrawCheck or other QA tools can help shift the focus away from unchecked production into ensuring you can grow in the direction you need for the right consumer.

Your workflow is the backbone of your production line. If there’s unnecessary complexity, you’re wasting time and losing money. Start by looking at every step of your process. Are there bottlenecks? Are your employees juggling too many tasks at once? Cutting down unnecessary steps can keep things moving smoothly from start to finish.

Here’s how you can streamline your workflow:

- Organized workstations: Keeping your production areas clean and organized means your team can move faster without fumbling around for tools or materials.

- Clear task delegation: Make sure everyone knows their role at every stage of production. Efficiency suffers when there’s confusion or overlap.

- Standardized procedures: Use consistent methods for rolling, packaging, and prepping, so there’s no guessing involved in the process.

4. Keep Your Inventory in Check

Managing inventory can be a nightmare if you’re not careful. Overproduce, and you’re left with product that might go stale. Underproduce, and you’re scrambling to keep up with demand. But with automation, you can track your stock in real-time and avoid those headaches altogether.

Inefficiency in inventory is one of the easiest ways to lose money. Knowing exactly what you have on hand—and where it’s going—makes it easier to meet demand and avoid unnecessary overproduction.

Optimize your inventory process with these tips:

- Set reorder points: Know when to order more materials based on usage rates to avoid running out or holding onto excess stock.

- Track usage patterns: Watch trends to anticipate how much flower, packaging, and supplies you’ll need based on production levels.

First in, first out: Rotate stock to make sure older product gets used first, preventing waste from aging or drying out flower.

Conclusion

Look, running an efficient operation should never mean cutting corners. You need to constantly make smart decisions that give you more control and better results. Automation, quality assurance, inventory management—it’s all part of the bigger picture. The more dialed in you are, the more you can grow without the stress.

Look for scalable solutions like:

- Strategic investments: Whether it’s in training, tools, or technology, invest in things that help you produce more efficiently without lowering standards.

- Partnerships with trusted suppliers: Work with suppliers that can keep up with your growth and ensure you’re getting fresh, quality materials every time.

- Evaluating results regularly: What works today might not work tomorrow. Always look for ways to fine-tune your process as your production scales.

Ready to stop wasting time and money?

Consult with RollPros today and see how you can make your production process as smooth as your next pre-roll.