In the US and Canada, cannabis pre roll and flower sales are nearly neck-and-neck, with pre rolls threatening to take the lead. It makes sense—consumers across demographics love them. They’re convenient, discreet, and require zero prep or tools besides a light and an occasional extra hand to block the wind.

Given cannabis pre rolls’ crowd-pleasing characteristics, it’s a lucrative sector to get into. It’s also fiercely competitive. The amount of brands crowding the shelves gives consumers the power to disregard any brand that provides them with a subpar experience. What’s the point in second chances when there are 15 other brands to try within arms’ reach?

To earn a loyal customer, cannabis brands must prioritize quality and consistency. Easy enough in a small operation, but for brands looking to scale up, automation is a necessity in order to maintain a consistent, quality cannabis pre roll.

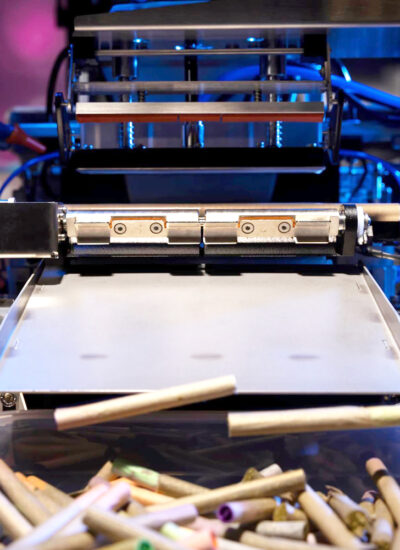

Incorporating a cannabis pre roll machine into your operation is the only way to successfully grow your pre roll business. Keep reading for what you need to know about automating cannabis pre roll production.