What packaging styles are most effective on dispensary shelves?

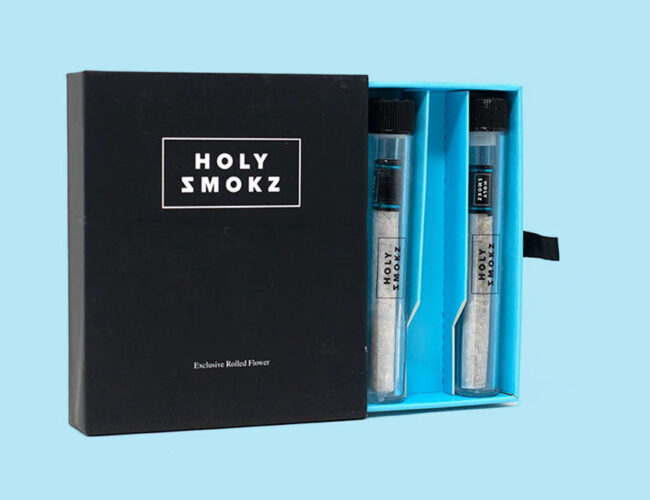

Slim tubes and vertically oriented boxes are highly effective due to their portability and efficient use of shelf space. Products with bold, clear branding and strong visual contrast consistently perform well.

Does packaging design influence consumer trust?

Yes. High-quality, professionally designed packaging signals that your product is safe, compliant, and made with care. This can directly increase a customer’s confidence at the point of sale.

How can I make my pre-rolls stand out without increasing cost?

You can make a strong impact through thoughtful design choices. Strategic use of color, typography, and packaging shape can elevate your visual presence without driving up production costs. A strong design foundation often delivers long-term returns in consumer engagement and loyalty.

Are limited edition packaging campaigns worth the investment?

Absolutely. Limited-time releases create urgency and exclusivity, which can boost sales and generate buzz. They also offer a flexible way to experiment with new branding or formats before committing to a permanent change.

Should I change packaging for different retail markets?

Yes. Localizing your packaging based on compliance requirements, consumer preferences, and regional trends helps improve product relevance. A tailored approach can improve sell-through rates and enhance your brand’s reputation across markets.