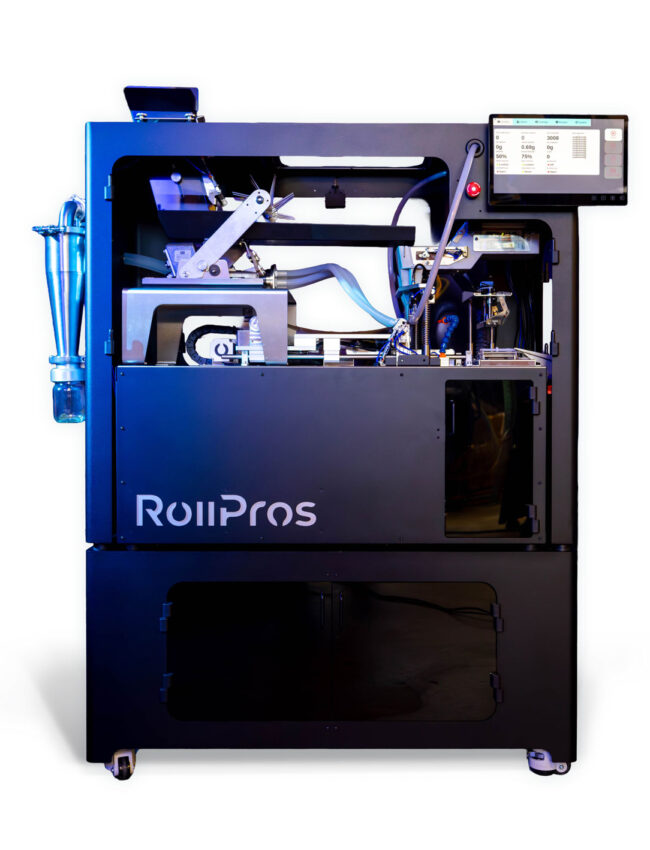

As the cannabis industry continues to grow and professionalize, brands are looking for smarter, faster, and more cost effective ways to scale. One of the most impactful investments a cannabis operation can make today is in an automatic pre roll machine.

From ensuring product consistency to dramatically reducing labor costs, automation isn’t just a nice-to-have. It’s becoming a competitive must have. Whether you’re a mid sized producer or a large scale operator, upgrading to a fully automated pre roll machine positions your brand to thrive in a fast moving market.

Below, we break down the top five benefits of investing in pre roll automation, what to consider when choosing a system, and the common questions cannabis brands ask before taking the leap.