For cannabis enthusiasts, achieving the perfect grind is essential for an optimal smoking or vaping experience. A weed grinder isn’t just a fancy accessory; it’s a crucial tool that significantly impacts the quality and consistency of your cannabis experience. Whether you’re a seasoned smoker or new to the scene, understanding how to use a weed grinder effectively can elevate your experience. This comprehensive guide will walk you through everything you need to know, from why grinding matters to choosing the right grinder for your needs.

The ROI of Automation: How Fast Can a Pre-Roll Machine Pay for Itself?

To meet these demands, cannabis brands across the United States and around the world are adopting automated solutions that increase production capacity, lower labor expenses, and reduce product waste. At the heart of this shift are automated pre-roll machines designed to roll joints with speed, precision, and uniformity.

However, before committing to a significant investment in automation technology, many companies ask the same important question: What kind of return on investment can we expect?

Understanding the ROI of a fully automated pre-roll machine is essential for making smart, informed decisions. In this guide, we’ll walk through what ROI means in the context of pre-roll automation, examine the key factors that impact it, and explain how quickly these machines can begin to pay for themselves.

What Does ROI Mean in Pre-Roll Automation?

Defining ROI in the Cannabis Industry

Return on Investment (ROI) is a key financial metric that helps businesses understand how much value or profit they receive in return for a specific expense. In the cannabis industry, where margins can be tight and operational efficiency is critical, ROI takes on even greater importance. When it comes to investing in automatic pre-roll machines, ROI helps determine how long it will take for the machine to generate enough savings and additional revenue to cover its cost.

For cannabis producers, this means measuring how the investment in automation translates into reduced labor costs, higher output, and less product waste. The goal is to understand not just when the machine pays for itself, but how it improves overall business performance over time.

Key Inputs That Influence ROI

When evaluating the ROI of a fully automated pre-roll machine, several important factors come into play. These variables impact both how quickly the machine pays itself off and how it continues to drive profitability in the long run:

- Initial Machine Cost

This includes the purchase price of the equipment as well as expenses for delivery, installation, calibration, and staff training. While this upfront investment may seem significant, it establishes the foundation for long-term operational efficiency. - Production Output

One of the clearest drivers of ROI is the volume of joints the machine can reliably produce. Higher output leads to more consistent product availability, increased sales opportunities, and faster financial recovery. - Labor Savings

Automation reduces the need for manual labor in the rolling process. This can significantly lower payroll costs, free up staff for higher-value tasks, and reduce reliance on hard-to-find skilled labor. - Waste Reduction

Automated machines deliver more precise and consistent fills than manual processes. This minimizes product loss caused by overpacking, underpacking, or errors during hand-rolling, which directly contributes to cost savings. - Maintenance and Ongoing Costs

While automated machines require routine maintenance, the cost of upkeep is typically predictable and far less than the variable costs associated with manual labor. It’s important to consider ongoing expenses like replacement parts, support services, and software updates when calculating true ROI.

Understanding how these inputs affect ROI allows operators to make informed purchasing decisions and build a realistic timeline for when they can expect a return on their investment. In many cases, a well-utilized machine can pay for itself in a matter of months and continue delivering value for years to come.

Typical ROI Timelines

Although return on investment will vary from business to business, most cannabis operators can expect to recover the full cost of a pre-roll automation system within three to twelve months of implementation. The exact timeline depends on several factors, including daily production volume, local labor rates, and the pricing structure of finished products.

Operators running high-output facilities with steady demand and efficient workflows tend to reach breakeven on the shorter end of that range. For these businesses, automation quickly becomes a strategic asset that drives growth and profitability.

Once the machine has paid for itself, the financial upside becomes increasingly clear. Every additional pre-roll produced adds directly to your profit margin. At that point, automation shifts from being a way to save money to being a reliable and scalable engine for generating revenue. It allows your operation to grow without a proportional increase in labor costs or production bottlenecks, creating long-term value well beyond the initial investment.

Key Factors That Impact ROI

- Daily Production Capacity and Speed

Not all machines perform at the same level. High-output automated pre-roll machines can consistently produce more than 3,000 joints per day. In contrast, even a skilled manual team may only produce 300 to 500. That kind of scale drives a significantly faster return on investment by increasing overall volume without increasing labor. - Reduction in Labor Costs

Labor remains one of the most expensive line items in cannabis production. Replacing multiple manual workers with a single trained machine operator can reduce payroll costs by tens of thousands of dollars each year. These savings directly improve margins and shorten the path to profitability. - Decrease in Product Waste and Human Error

Hand-rolled joints are often inconsistent, leading to overfilled, underfilled, or improperly packed products. This results in wasted material and potential compliance issues. Automated machines are designed for accuracy, producing uniform pre-rolls that reduce product loss and minimize costly mistakes. - Ongoing Maintenance and Training

While machines do require routine care, maintenance expenses are generally stable and easier to forecast than variable labor costs. Training operators to run and maintain the equipment properly helps avoid downtime, extend the life of the machine, and ensure consistent performance over time.

Sample Cost-Benefit Breakdown

| Factor | Manual Production | Automated Production |

|---|---|---|

| Daily Output | 500 joints | 3,000 joints |

| Labor Cost | $800/day | $150/day |

| Waste | 10% | 2% |

| Cost per Joint | $1.60 | $0.50 |

| Monthly Cost | $24,000 | $7,500 |

How Fast Can a Pre-Roll Machine Pay for Itself?

Real-World ROI Timelines

For many cannabis producers, the return on investment from an automated pre-roll machine can be surprisingly quick. Depending on your production scale, staffing model, and overall efficiency, most operators report breaking even within 3 to 6 months. Larger facilities running multiple shifts per day often reach full ROI even faster, making automation a powerful tool for accelerating growth.

Factors That Accelerate Payoff

- High daily output: The more joints you produce, the faster you cover your investment and begin generating pure profit.

- Premium product pricing: Brands that command higher prices per pre-roll generate more revenue per unit, speeding up ROI.

- Operational efficiency: Well-trained staff and streamlined workflows ensure the machine runs at peak capacity, avoiding downtime and bottlenecks.

ROI Scenarios by Business Type

- Small Batch Producer: With lower production volume, breakeven typically occurs within 9 to 12 months.

- Mid-Sized Operation: Moderate volume and efficient processes usually lead to breakeven in 6 to 9 months.

- High-Volume Brand: Businesses operating at full capacity across multiple shifts often reach breakeven in just 3 to 6 months.

Manual vs. Automated Production: A Cost Comparison

The Labor-Intensive Nature of Manual Production

Manual pre-roll production depends heavily on skilled labor. While experienced rollers can produce quality joints, the process is often slow, inconsistent, and challenging to scale. Even top-performing teams face limitations in output due to fatigue, human error, and the natural variability that comes with manual work. These factors drive up labor costs and restrict a company’s ability to grow without hiring additional staff.

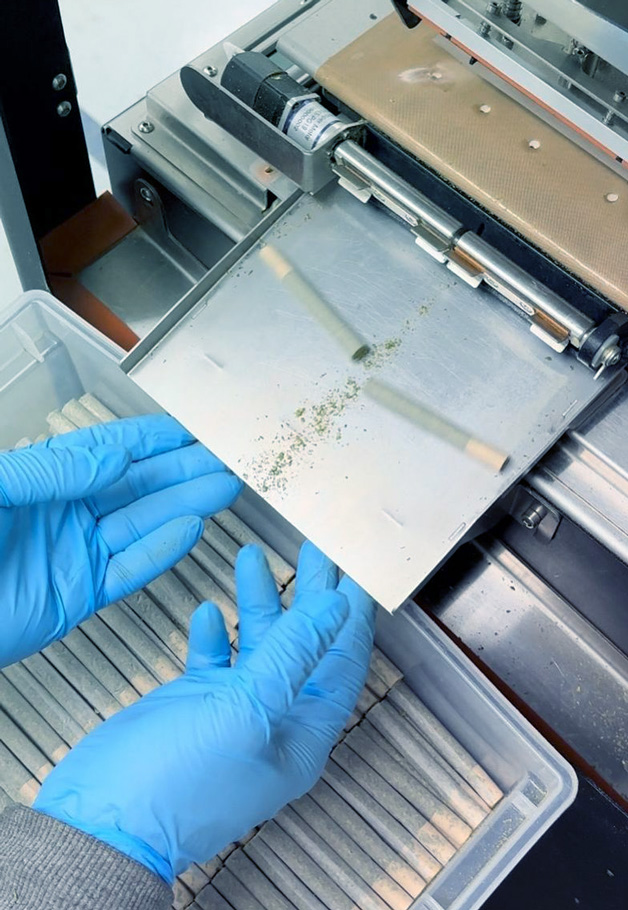

The Efficiency of Automated Workflows

Automated pre-roll machines are designed to optimize every stage of production. By minimizing manual input, these systems deliver:

- Significantly faster production cycles

- Lower reliance on large labor teams

- Easier scalability as demand increases

- Consistent, uniform pre-rolls that meet quality standards every time

Over time, automation creates a more stable and cost-effective operation. It allows producers to maintain quality, reduce overhead, and increase throughput, all while positioning the business for long-term growth and competitiveness.

Technology Spotlight: Tools That Maximize ROI

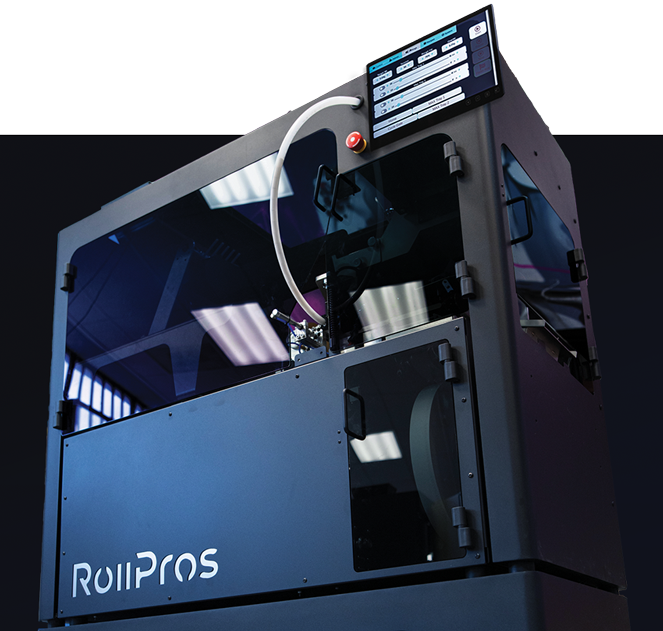

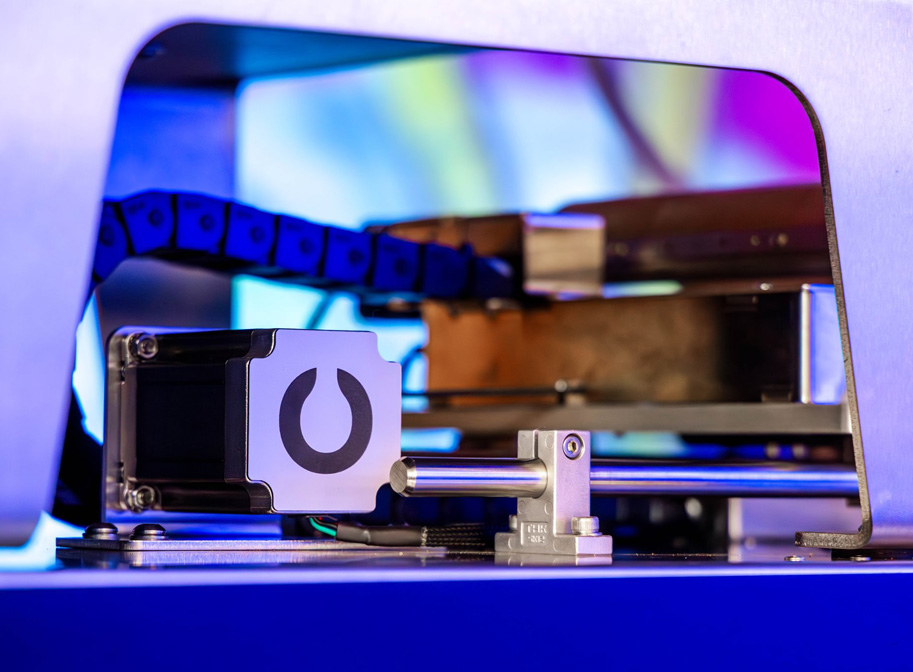

RollPros and Other Advanced Equipment

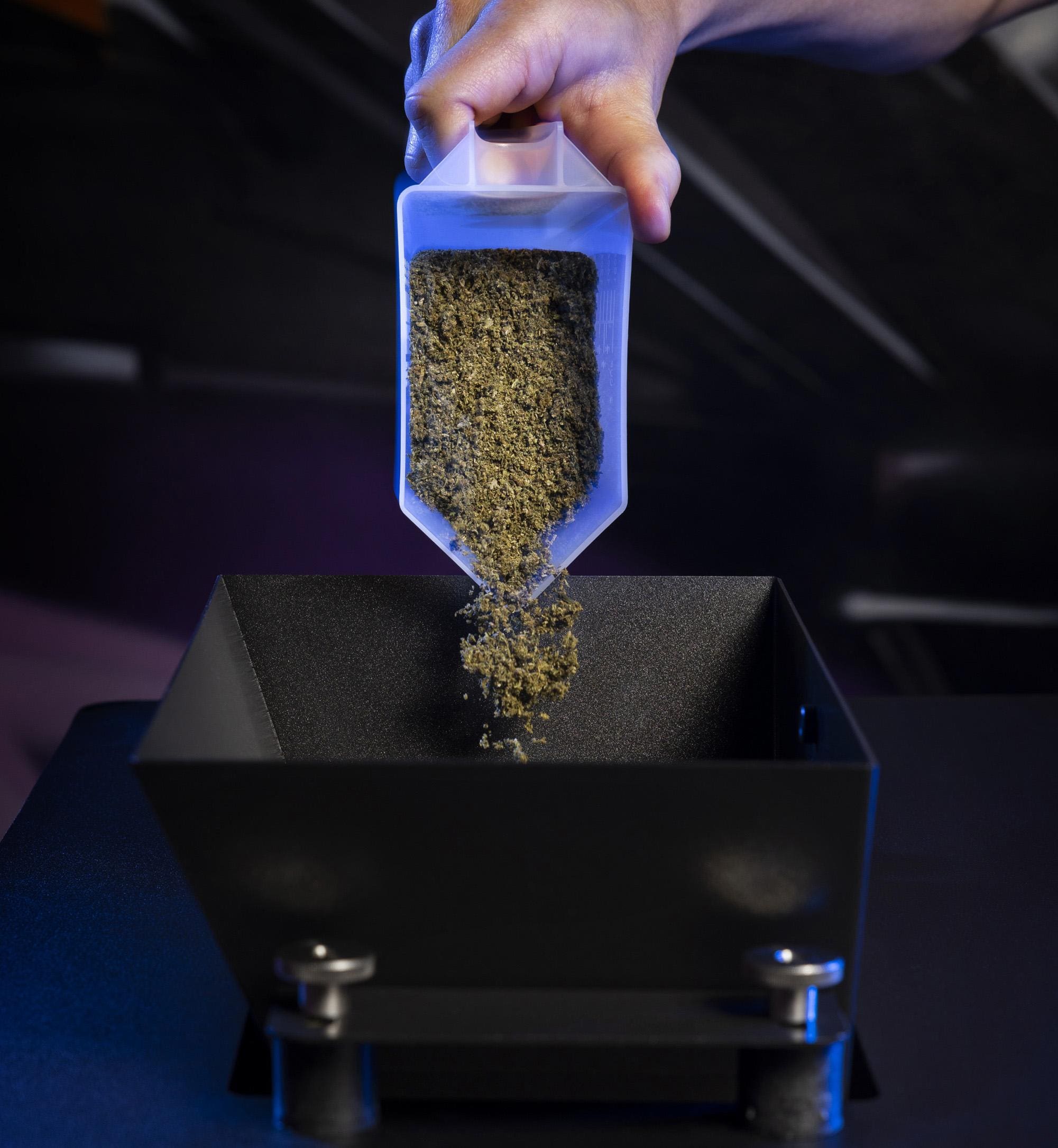

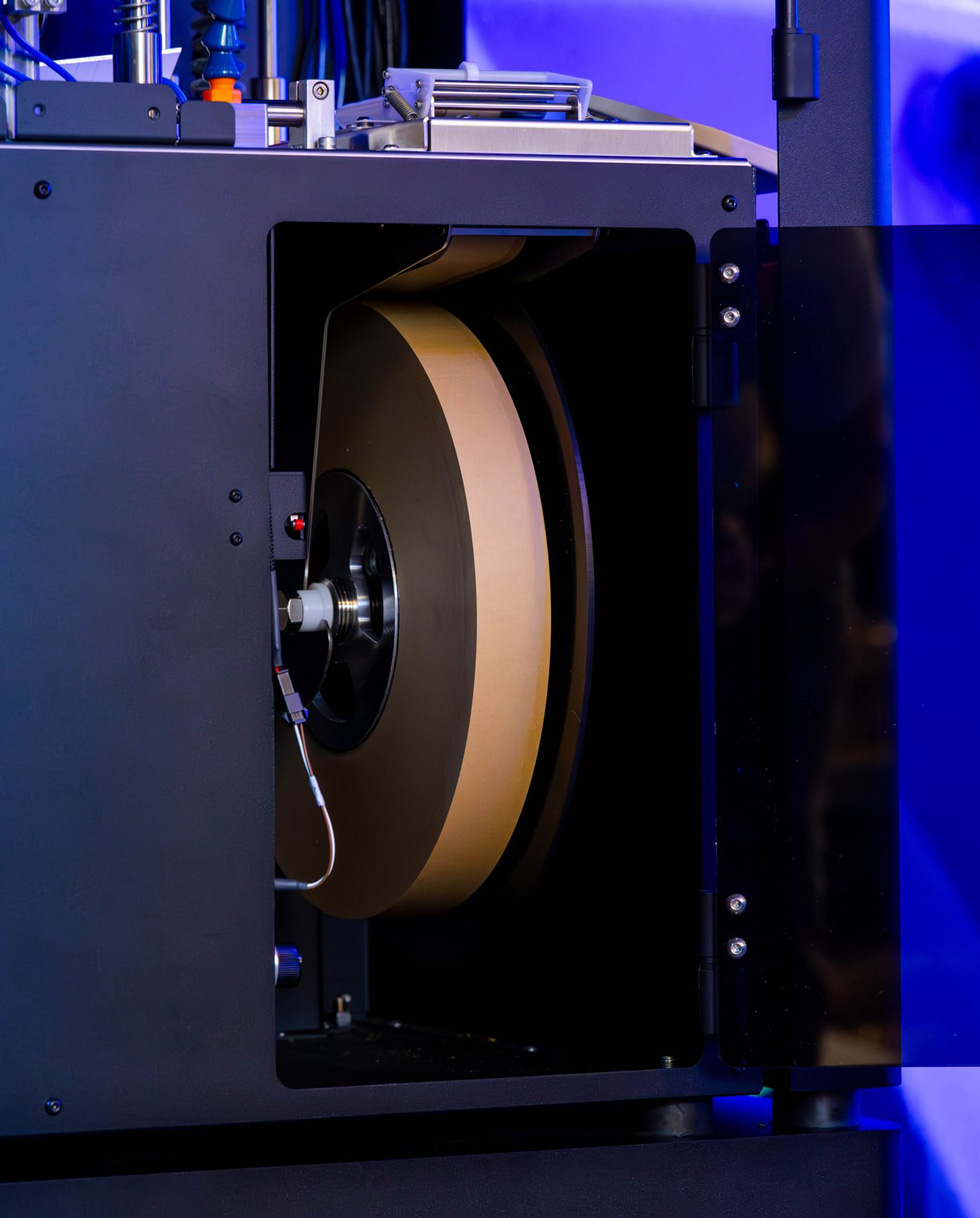

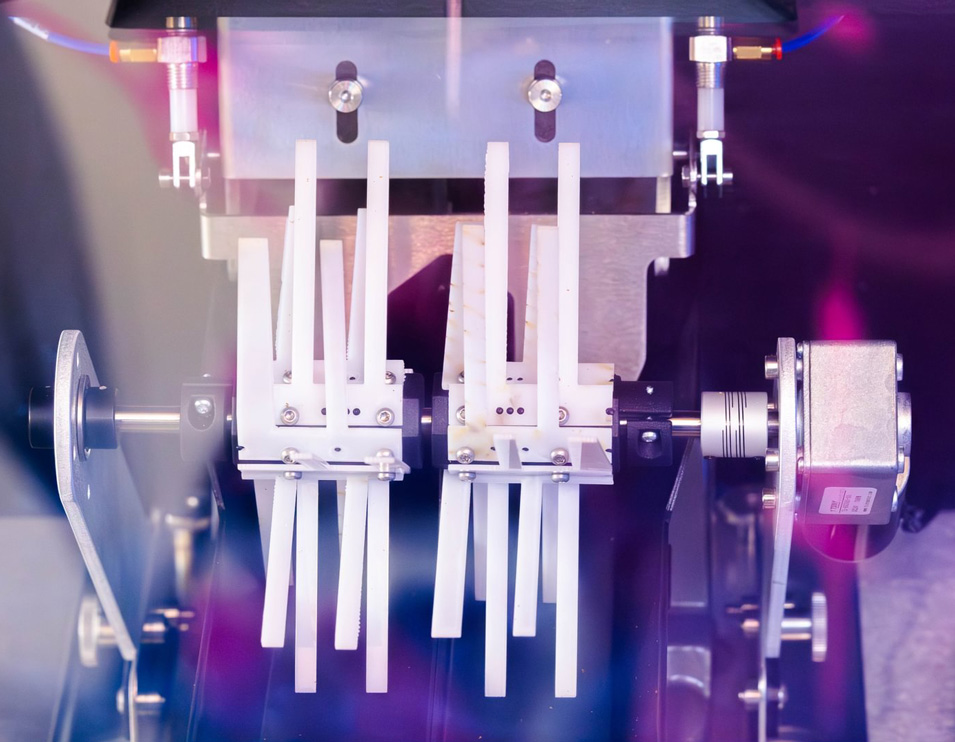

RollPros’ pre-roll systems are built to streamline and automate the entire production process. Unlike semi-automated machines that still rely on manual input, RollPros delivers end-to-end automation—from flower loading to final output. These machines are engineered for speed, precision, and consistency, helping producers scale faster while maintaining quality.

Supporting Equipment That Enhances Efficiency

Maximizing ROI goes beyond just the pre-roll machine. Additional tools can further improve throughput and reduce labor strain:

- Cone loaders accelerate the filling process, reducing prep time.

- Precision weighers guarantee accurate fill weights, minimizing product waste and ensuring compliance.

- Automated sealers and labelers cut down on finishing time and streamline packaging workflows.

The Role of Smart Automation

Many modern machines now come equipped with built-in sensors and performance tracking software. These advanced features help teams:

- Minimize unplanned downtime through real-time alerts and diagnostics

- Improve output efficiency by identifying workflow bottlenecks

- Leverage data to fine-tune production and optimize ROI over time

Smart automation turns machines into strategic tools, empowering operators to make informed decisions that drive consistent performance and long-term profitability.

Beyond Savings: Strategic Benefits of Automation

Faster Time to Market

Automation dramatically speeds up production cycles, allowing brands to bring new products to market much faster. This agility enables companies to capitalize on emerging trends and quickly meet sudden increases in demand, giving them a competitive edge in a fast-moving industry.

Improved Product Quality

Automated machines produce joints with consistent weight, density, and packing quality every time. This uniformity leads to higher customer satisfaction, fewer returns or complaints, and strengthens brand loyalty by delivering a dependable product experience.

Enhanced Brand Reputation

Offering a consistently high-quality pre-roll builds trust with consumers and positions your brand as a premium player in the market. This reputation not only supports stronger pricing but also attracts repeat business and positive word-of-mouth referrals, helping to grow your customer base organically.

Scalable Growth Without Labor Challenges

Automated systems make scaling your operation more straightforward by reducing reliance on large labor teams. This reduces overhead costs, lowers training time, and minimizes risks associated with staff turnover. Businesses can expand production capacity efficiently, improving profitability while maintaining control over quality and operational complexity.

Challenges and Considerations

Upfront Investment

The initial purchase price of a high-quality pre-roll machine can represent a substantial financial commitment. It is crucial for companies to carefully evaluate whether the machine’s capacity and features align with their current production volume and long-term operational goals. Investing in the wrong equipment can tie up capital and slow down ROI.

Learning Curve

Introducing new machinery requires staff to learn how to operate and maintain it effectively. While this training demands time and resources upfront, it is typically a one-time investment that pays off through improved efficiency and reduced errors. Proper training ensures the machine runs smoothly and maximizes output over its lifetime.

Risk of Underuse

Acquiring a high-capacity machine without sufficient production demand can lead to underutilization, extending the time it takes to recoup costs. It is essential to select equipment that matches your current and near-future business needs to avoid turning the machine into a costly asset that sits idle.

Maintenance and Utilization

Ongoing maintenance is vital to keep the machine operating at peak performance. Regular servicing and timely repairs help prevent unexpected downtime and costly breakdowns. Additionally, consistent use is necessary to justify the investment; machines that remain idle or are poorly managed become sunk costs rather than valuable assets.

Challenges and Considerations

The return on investment for a fully automated pre-roll machine is not just a theoretical concept; it is a proven outcome in the cannabis industry. These machines provide a tangible solution to reducing labor costs, cutting waste, and improving consistency in production. For many cannabis operations, automation has proven to be the key to transforming a slow, bottlenecked process into one that runs smoothly and efficiently.

While ROI timelines can vary based on the size and efficiency of the operation, many businesses recover their initial investment within just a few months when the equipment is properly utilized. Beyond simple cost savings, automation can drive faster growth, enhance product quality, and position your business more competitively in the marketplace.

If you are considering automation for your operation, now is the time to act. Take the opportunity to evaluate your current processes, consult with equipment vendors, and see how the right pre-roll machine can be a powerful tool in helping your business reach its next level of success.