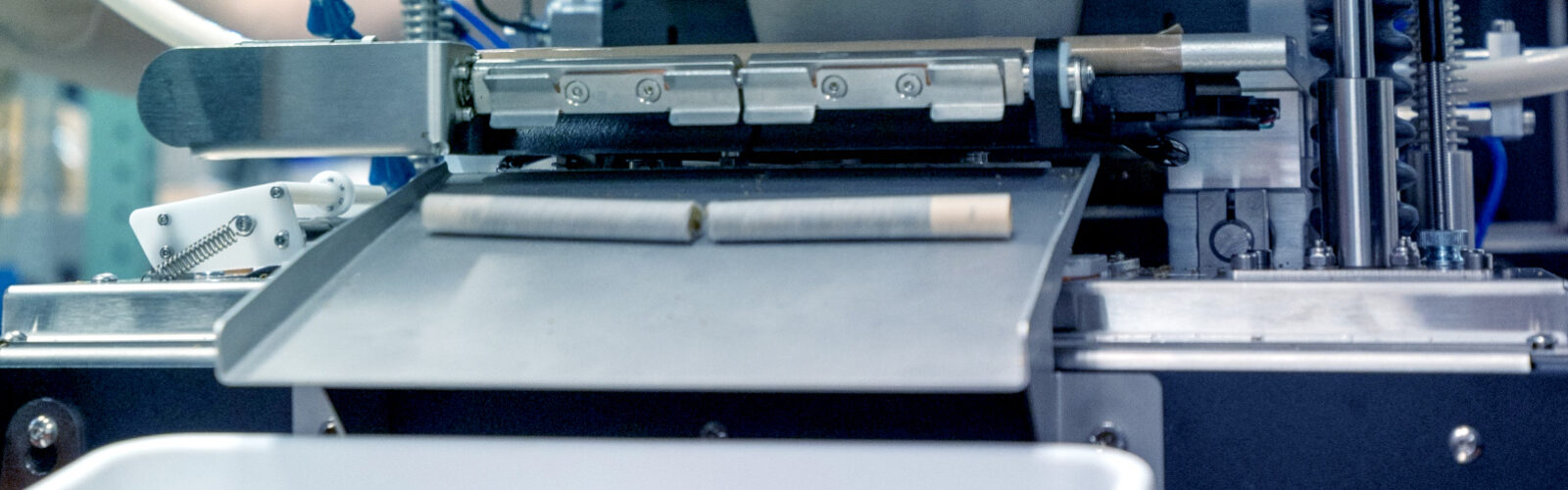

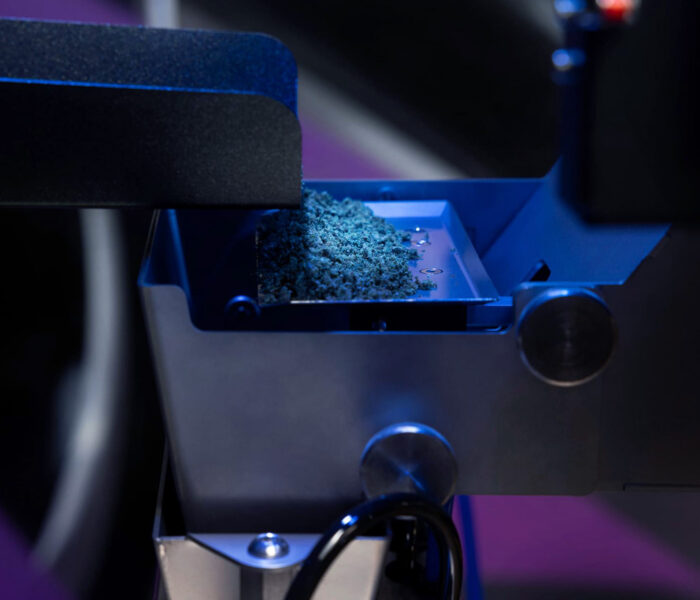

For large-scale producers, maintaining commercial pre-roll machines comes with unique challenges. These machines handle high volumes of production, so they require more attention than smaller, less frequently used machines. Daily cleaning, weekly maintenance, and regular servicing are essential to keeping them running smoothly.

- Tailored Maintenance: For bigger operations, daily cleaning is a must, and weekly deep cleaning should be non-negotiable.

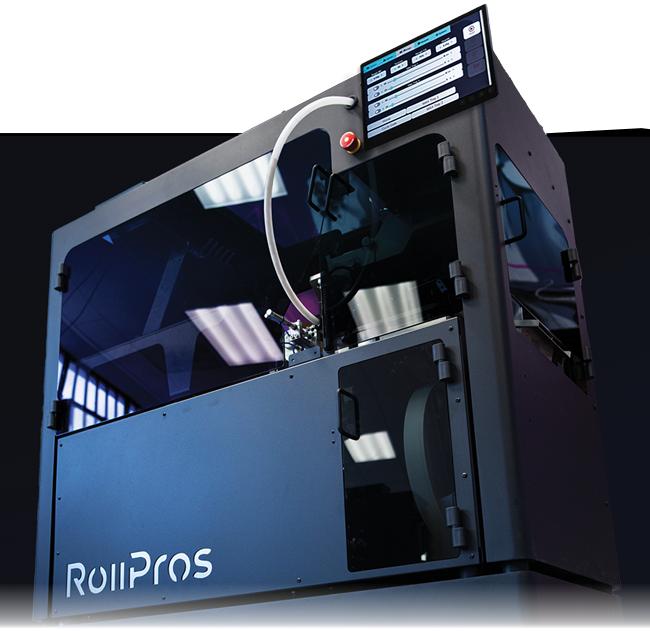

- Pro Support: For high-volume commercial pre-roll machines, having professional servicing and manufacturer support is key. It’s your safety net for when things get too complex to handle in-house.

Working with a machine built domestically makes it easier to access parts and technicians, reducing downtime and helping your operation stay efficient.