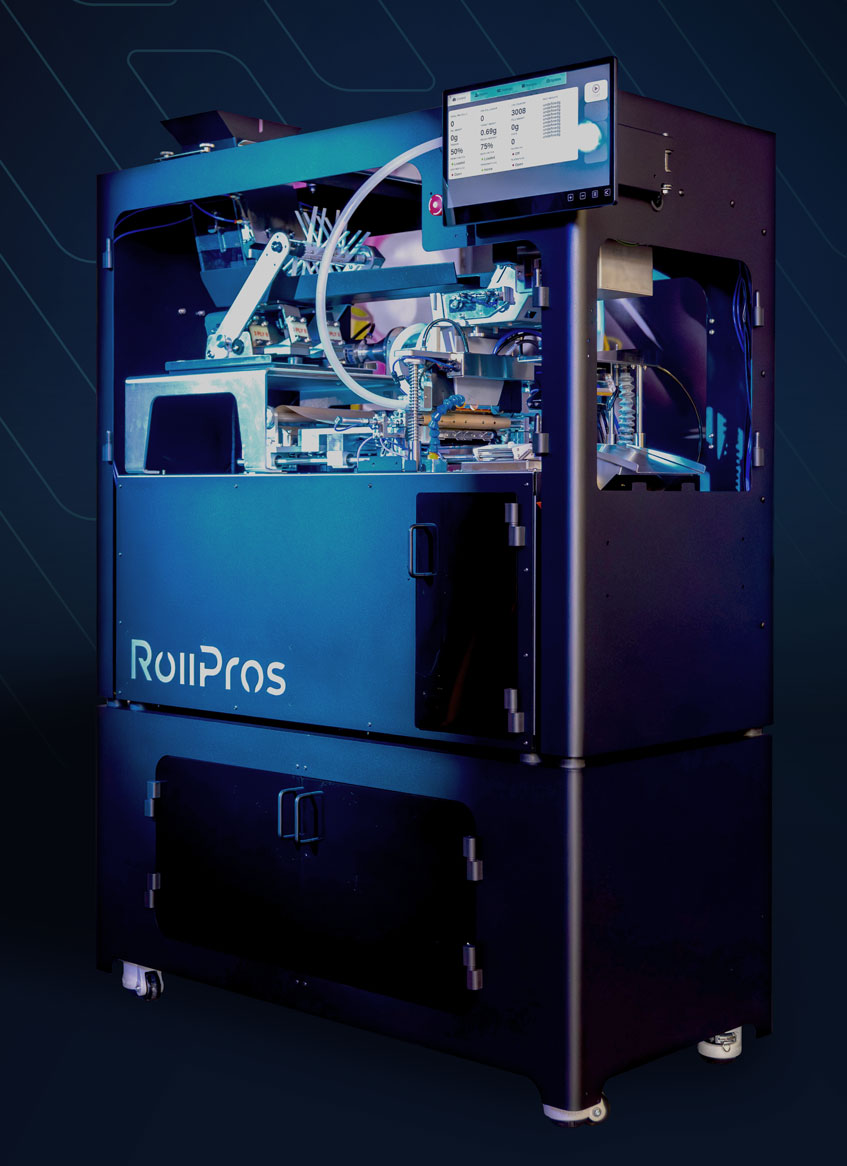

In today’s fast paced cannabis industry, automation is the key to meeting rising consumer demand for consistent, high quality prerolls. Pre roll machines have revolutionized the way cannabis is processed and packaged, enabling manufacturers to increase efficiency, reduce manual labor, and maintain consistent product standards. However, with these technological advances come new safety responsibilities. Operating a joint rolling machine, especially at scale, involves exposure to mechanical, electrical, and environmental risks that must be proactively managed.

This guide outlines comprehensive safety measures to help cannabis operators use pre roll automation responsibly and compliantly. From pre-operation checklists to facility wide protocols, following these practices can reduce risk, maintain compliance with regulatory standards, and foster a safer working environment.