In today’s fast paced industrial landscape, automation is more than just a convenience—it’s a necessity for businesses striving to remain competitive. From automotive assembly lines to pharmaceutical manufacturing, it enhances productivity, reduces operational costs, and ensures product consistency. By integrating advanced robotics, AI driven performance control, and data driven optimization, industries are pushing the boundaries of what’s possible in production.

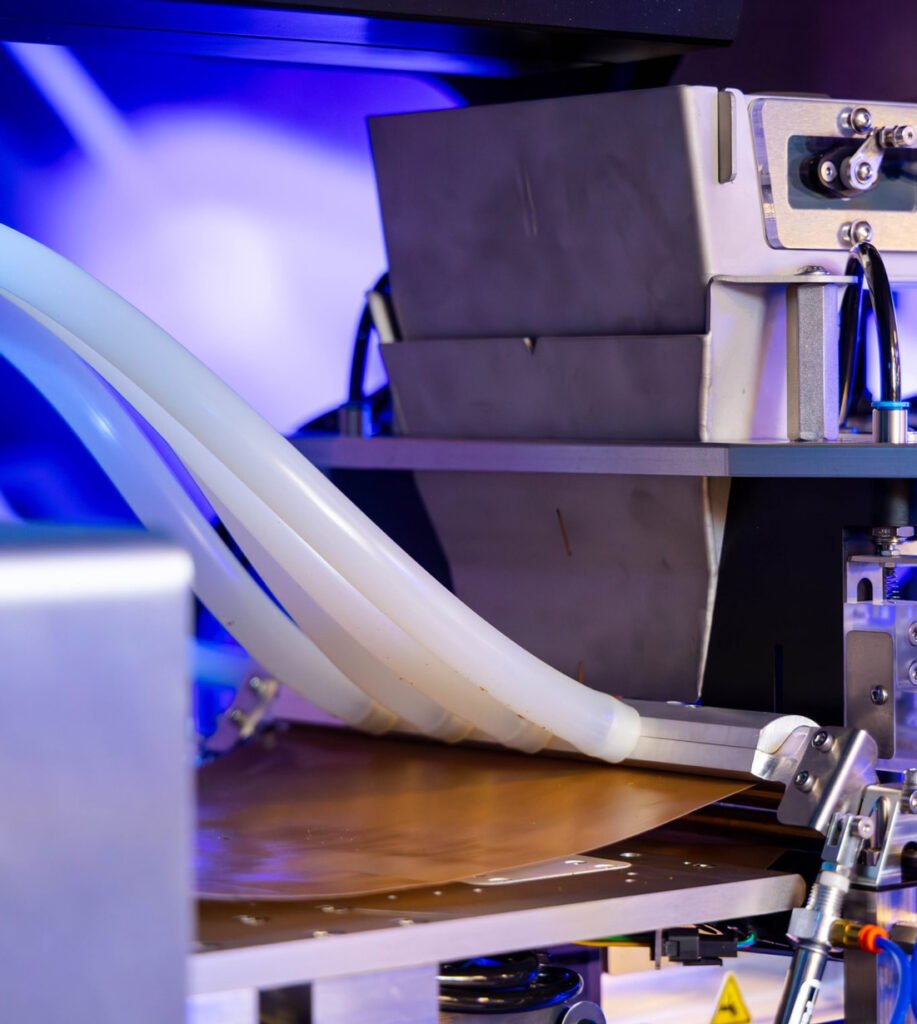

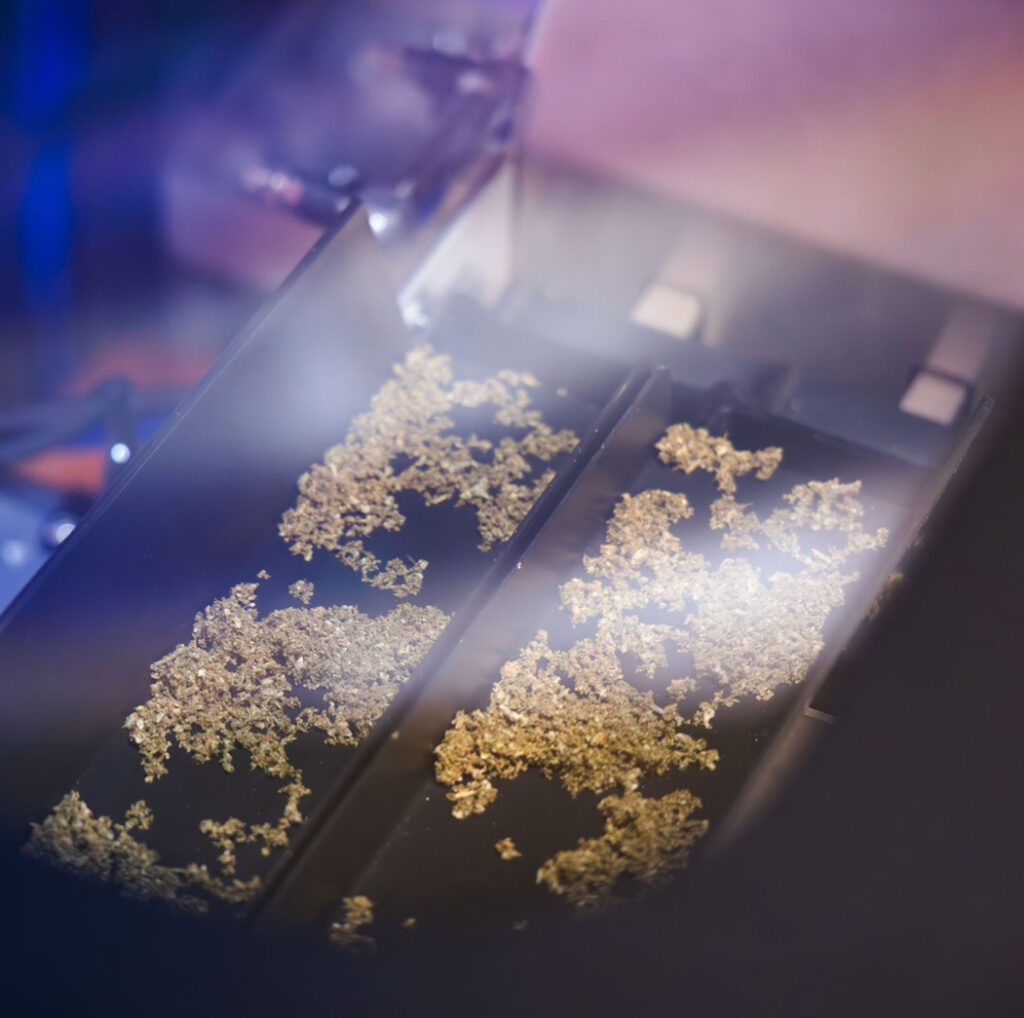

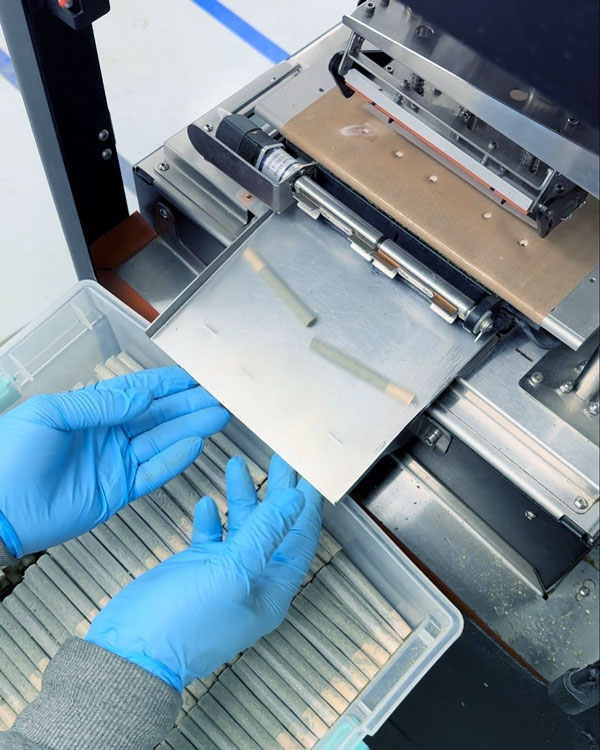

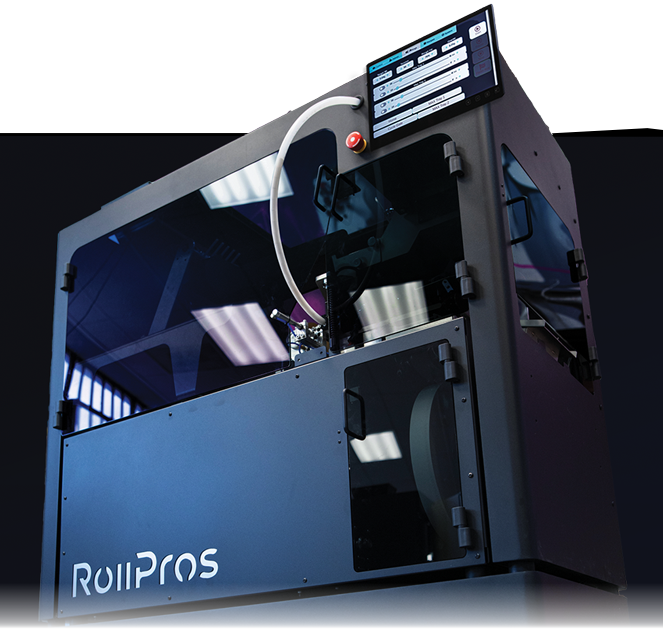

One sector experiencing a major transformation through mechanization is the cannabis industry. The demand for high grade, precisely crafted products has led to the rise of automated pre-roll machines, which replace traditionally labor intensive processes with precision engineering. These machines not only improve uniformity in weight and density but also drastically increase output, allowing producers to scale operations without compromising standard.

Beyond efficiency, automation in pre-roll production minimizes human error, reduces material waste, and ensures compliance with field regulations. By standardizing the rolling process, brands can maintain a reliable product experience, which is crucial in an industry where consumer trust is key. As technology continues to evolve, the integration of AI and machine learning will further refine these processes, making automated pre-roll production smarter, faster, and even more adaptable to market demands.

From cost savings to improved product performance, optimization is shaping the future of output across industries, and in cannabis, it’s proving to be a game changer.