Introduction – Efficiency Meets Innovation in Cannabis Production

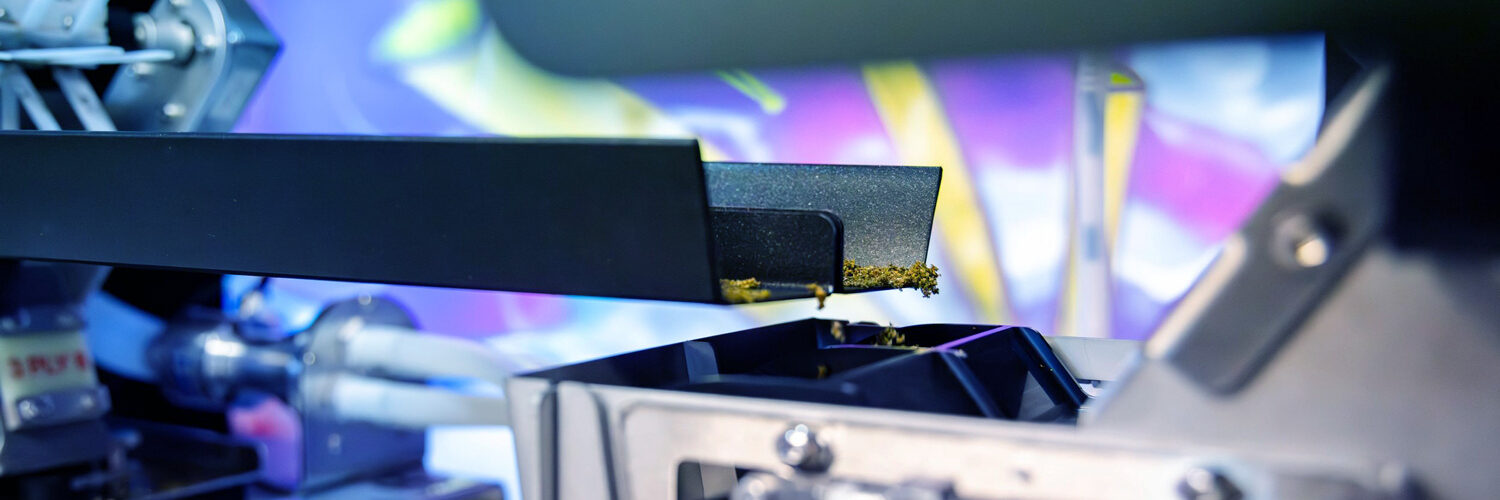

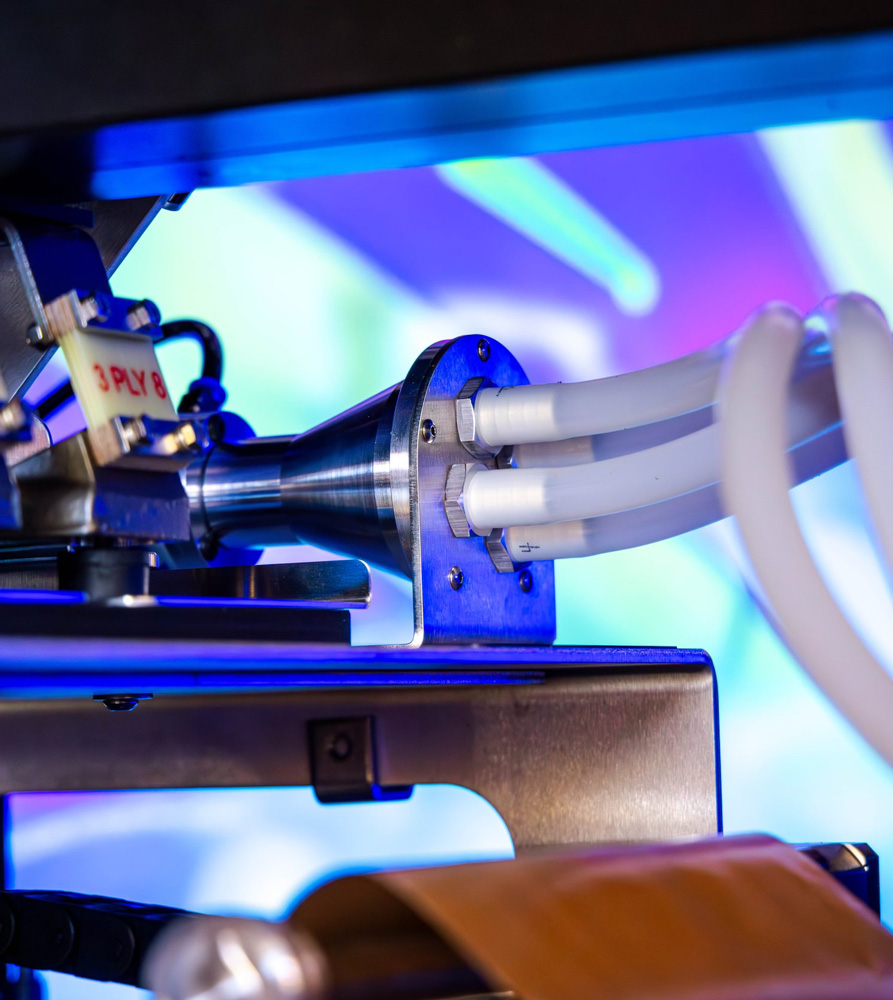

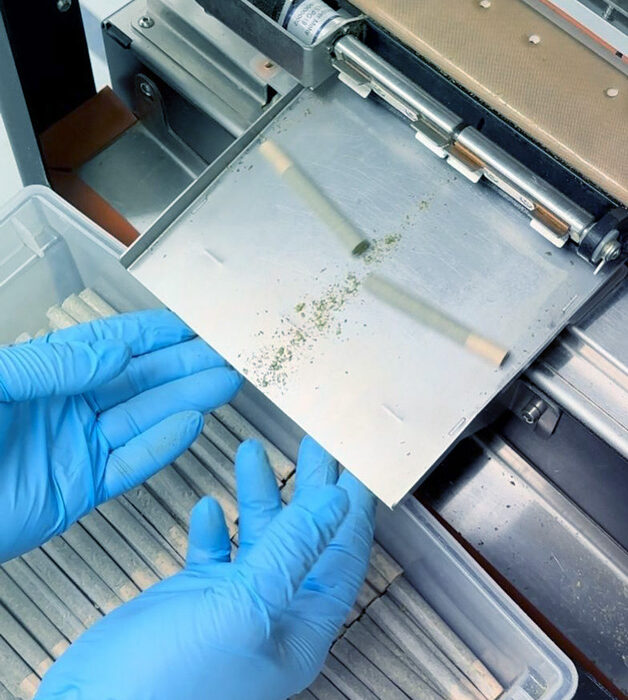

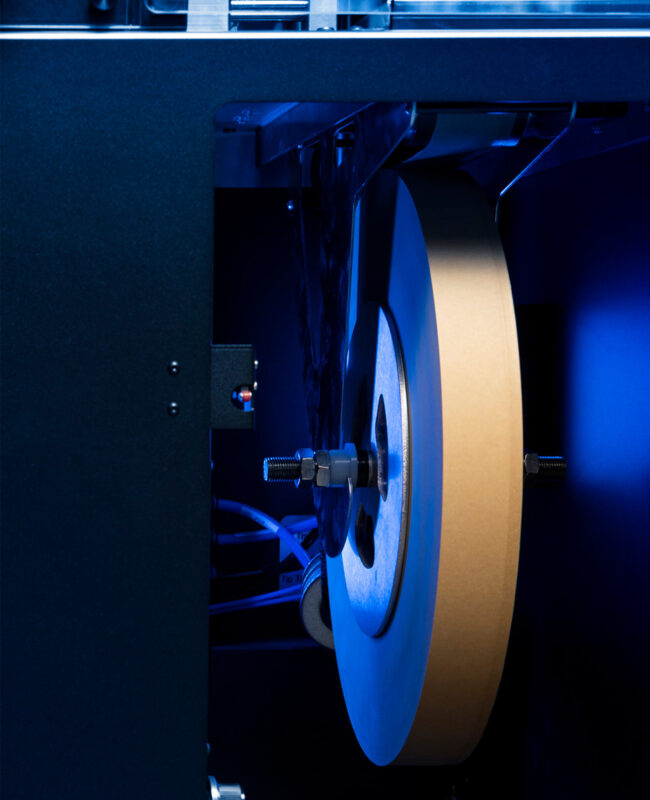

As the cannabis industry continues its rapid maturation, the pressure on producers to operate with greater efficiency, consistency, and compliance has never been higher. With evolving regulations, increasing consumer demand, and expanding competition, cannabis brands are looking for smarter ways to scale—and fast. One sector undergoing a dramatic transformation is pre-roll production, fueled by the rise of cannabis pre-roll automated machines.

What was once a highly manual, time-consuming process is now being revolutionized by advanced automation technologies. These machines are enabling producers to meet the surging demand for prerolls with unparalleled speed, precision, and reliability. From boutique craft brands to multi-state operators, automation is helping businesses reduce labor costs, minimize human error, and deliver a consistently high-quality product at scale.