The pre-roll market is booming, and for good reason. Consumers love the convenience and consistency of pre-rolled cannabis products. But behind every perfectly crafted pre-roll is a sophisticated process, often powered by advanced pre-roll machines like the RollPros Blackbird. In this blog post, we’ll take you on a journey from raw cannabis flower to the finished product, exploring each step of the pre-roll machine process. Understanding this process will illuminate the efficiency, precision, and quality that these machines bring to the cannabis industry.

From Flower to Finished Product: The Step-by-Step Process of a Pre Roll Machine

Introduction

Preparing the Cannabis Flower

The journey begins with the raw cannabis flower. The quality of the final product hinges on the quality of the starting material. Therefore, careful selection and preparation of the flower are paramount.

Grinding for Consistency

The first step in preparing the flower is grinding. Achieving a consistent grind is crucial for even burning and a smooth smoking experience. Pre-roll machines require a specific grind size to function optimally. If the grind is too fine, it can clog the machine and lead to uneven density in the pre-roll. If it’s too coarse, the pre-roll might burn unevenly or too quickly. High-quality grinders are used to ensure uniformity, and many machines have built-in grinding mechanisms. The ideal grind is often described as a medium consistency, similar to what you’d use for rolling by hand. This ensures proper airflow and even combustion.

Moisture Control and Storage

Moisture content plays a significant role in the grinding and filling process. Flower that is too dry can become brittle and dusty, while flower that is too moist can clump and clog the machine. Proper moisture control is essential for maintaining the integrity of the flower and ensuring efficient processing. Optimal humidity levels are maintained during storage to prevent degradation and preserve terpenes and other valuable compounds. The storage environment must be cool, dark, and well-ventilated. Sealed containers or humidity-controlled environments are often used to maintain the ideal moisture content, typically between 55% and 62% relative humidity.

Loading the Pre Roll Machine

Once the flower is properly prepared, it’s time to load it into the pre-roll machine. The loading process varies depending on the type of machine. Some machines have large hoppers that can hold substantial amounts of ground flower, while others require smaller, more frequent refills. The design of the machine is critical for efficient loading. Easy access and clear visibility are essential for operators to monitor the process and make adjustments as needed. Ergonomic considerations also play a role, as operators often load machines for extended periods. The machine is calibrated to dispense the precise amount of ground flower required for each pre-roll. This calibration ensures consistency and accuracy in every product.

Filling and Packing the Pre Rolls

The heart of the pre-roll machine process is the filling and packing of the pre-rolls. This is where precision and automation shine.

Precision Weighing for Accuracy

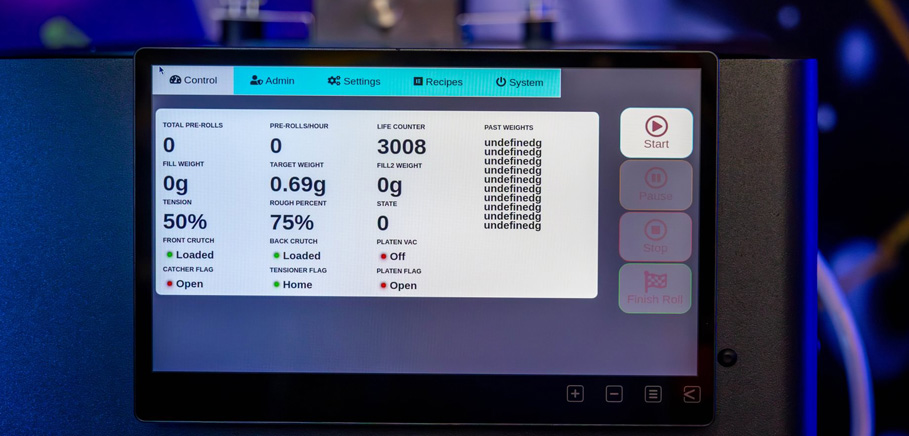

One of the key advantages of using a pre-roll machine is the ability to achieve precise weighing. Each pre-roll needs to contain a specific amount of cannabis, and manual filling can lead to inconsistencies. Pre-roll machines use highly accurate scales to measure out the exact weight of the flower for each cone. This precision ensures compliance with regulations and delivers a consistent experience for consumers. The machines are calibrated regularly to maintain accuracy, and quality control checks are performed to verify the weights. Some advanced machines even have real-time weight monitoring and adjustment systems.

Rolling or Tamping and Compaction

After the flower is weighed, it needs to be rolled or tamped and compacted into either a premade cone or a rolled joint like those produced by the Blackbird. For a budget product with low quality flower, cones are the best fit, and they are filled with a tamping mechanism. For a high quality product that offers a premium experience to consumers, the Blackbird rolls joints with single sheets of paper. It is difficult to achieve even density with a tamping mechanism because of the varied width of a cone. Blackbird produced joints use a patented technology called TruRoll that uses radial compaction when rolling the joint. Meaning, the compaction happens from every direction all at once, rather than from one end forced downward. Other inferior machines use vibration or centrifugal force to attempt to produce even density pre rolls. The goal is to create a pre-roll that burns evenly and provides a consistent draw.

Sealing the Preroll

Once the pre-roll is filled and rolled or packed, the next step is twisting or sealing. This is what keeps the cannabis securely inside the pre roll.

Finalizing the Pre Roll Shape

With cones, the twisting and sealing process not only secures the contents but also finalizes the shape of the pre-roll. Machines are designed to create a consistent and aesthetically pleasing twist at the end of each pre-roll. Blackbird produced joints are sealed by wetting a gumline that runs lengthwise along the joint. They are left open at one end, rather than hiding the contents of the product. When fresh, sticky flower is used and is kept in a moisture-proof container, this produces a joint that smells, tastes, and feels better than cone-based joints.

Minimizing Waste and Ensuring Product Integrity

Throughout the process, minimizing waste and ensuring product integrity are critical considerations. Machines are designed to minimize spillage and ensure that each pre-roll is sealed correctly. This reduces waste and ensures that the final product meets quality standards. Automated quality control checks are often integrated into the process to identify and remove any defective pre-rolls. This ensures that only high-quality products reach the consumer.

Packaging and Distribution

The final stages of the pre-roll machine process involve packaging and distribution. This is where the finished pre-rolls are prepared for sale and shipment.

Automated Sorting and Counting

After the pre-rolls are sealed, they are often sorted and counted by automated systems. This ensures accurate inventory management and efficient packaging. Machines can count pre-rolls with high precision, reducing the risk of errors. Automated sorting systems can also separate pre-rolls by strain, size, or other criteria. This streamlines the packaging process and ensures that the correct products are packaged together.

Sealing for Freshness and Compliance

Proper sealing is essential for maintaining the freshness of the pre-rolls and complying with regulations. Pre-roll machines often include sealing mechanisms that create airtight packages. This prevents the cannabis from drying out and preserves its potency and flavor. Compliance with packaging regulations is also a critical consideration. Machines can be integrated with labeling systems to ensure that each package includes the required information. This includes warnings, strain information, and other details.

Advantages of Using a Pre Roll Machine

The benefits of using a pre-roll machine are numerous, spanning from efficiency to product quality.

Increased Efficiency and Scalability

Pre-roll machines significantly increase the efficiency of pre-roll production. They can produce hundreds or even thousands of pre-rolls per hour, far exceeding the capabilities of manual production. This increased efficiency allows businesses to scale their operations and meet growing demand. Automation reduces labor costs and frees up staff to focus on other tasks.

Enhanced Product Consistency

One of the most significant advantages of pre-roll machines is the enhanced product consistency. Each pre-roll is filled, packed, and sealed with the same precision, ensuring a uniform experience for consumers. This consistency builds brand loyalty and customer satisfaction. Consumers know what to expect from each pre-roll, leading to repeat business.

Cost Savings and Waste Reduction

While the initial investment in a pre-roll machine can be substantial, the long-term cost savings can be significant. Automation reduces labor costs, and precise filling minimizes waste. This leads to a more cost-effective production process. Waste reduction is not only good for the bottom line but also for the environment. By minimizing spillage and ensuring proper sealing, pre-roll machines reduce the amount of cannabis that is wasted.

Conclusion

The process of creating pre-rolls with a machine is a complex yet efficient operation that involves several crucial steps. From preparing the cannabis flower to the final packaging, each stage is vital in ensuring the quality and consistency of the product. Pre-roll machines offer numerous advantages, including increased efficiency, enhanced product consistency, and cost savings. These machines are revolutionizing the cannabis industry, making it possible to meet the growing demand for pre-rolled products while maintaining high standards of quality and compliance. As technology continues to advance, we can expect even more sophisticated pre-roll machines that further streamline the production process and enhance the consumer experience.