The cannabis industry is witnessing an unprecedented surge in demand for pre-rolled products. As more states and countries legalize cannabis for medical and recreational use, the market for pre rolls continues to expand at a rapid pace. These ready to use products offer unparalleled convenience, making them a popular choice among consumers who value ease of use and consistency in their cannabis experience.

Ensuring Consistent Quality in Pre Roll Production

Pre rolls cater to a wide range of users, from novices exploring cannabis for the first time to seasoned enthusiasts looking for a reliable and hassle-free option. However, meeting the growing demand while maintaining consistent quality presents significant challenges. Consumers have high expectations for pre rolls to deliver a smooth, even burn and a predictable experience every time. Failure to meet these expectations can lead to dissatisfaction, erode brand loyalty, and even harm a company’s reputation.

Ensuring high standards in pre roll manufacturing is not just about meeting consumer preferences; it’s also a matter of adhering to strict industry regulations. The process involves overcoming challenges such as variability in raw material quality, manual production errors, and inconsistencies in product weight and filling. Successfully addressing these issues is critical for producing a superior product that satisfies both customers and regulatory bodies, ultimately positioning the brand as a trusted leader in the competitive cannabis market.

Key components of pre-roll manufacturing include:

Rolling

The process begins with forming the structure of the pre roll using specialized rolling paper. These materials are chosen not only for their functionality but also for their impact on the smoking experience, such as burn rate and flavor retention. Precision is essential to maintain consistency in size, shape, and overall appearance.

Filling

Achieving an even distribution of ground cannabis is crucial for a uniform burn. The cannabis must be ground to an optimal particle size, fine enough for smooth rolling but not so fine that it restricts airflow. Automated filling equipment ensures precise cannabis placement, minimizing waste and maximizing efficiency

Sealing and Packaging

Once filled, pre rolls are sealed to protect the contents from spilling and to preserve potency and freshness. Packaging adds another layer of protection, ensuring the product withstands transportation while maintaining its quality. Modern packaging solutions often include tamper-evident seals, and child resistant designs to meet regulatory requirements and enhance consumer safety.

Steps in Pre Roll Production

Sourcing High-Quality Raw Materials

The foundation of any top-tier pre roll lies in the quality of its raw materials. The cannabis flower used in pre roll production plays a critical role in determining the flavor, aroma, functionality, and overall consumer experience. To achieve consistent excellence, manufacturers must prioritize the careful selection of raw materials that meet stringent quality standards.

1. Selecting Cannabis Strains with Consistent Profiles

Cannabis strains differ widely in their cannabinoid and terpene profiles, which directly impact the effects and sensory experience of the pre roll. Strains with consistent profiles allow manufacturers to deliver predictable and reliable products to their consumers.

- Cannabinoid Profiles: Ensuring consistent THC and CBD levels is essential for meeting potency expectations and maintaining regulatory compliance.

- Terpene Content: Rich terpene profiles enhance the flavor and aroma of the pre roll, contributing to a more enjoyable smoking experience.

- Strain Variability Management: Partnering with cultivators who use standardized cultivation practices can help minimize variability in strain characteristics.

2. Evaluating Flower Quality

The quality of the flower itself, its appearance, texture, and density, affects both production and user satisfaction.

- Trim Quality: Leaves, stems, and other excess plant material should be removed to avoid harsh smoke or inconsistent grinding.

- Bud Density: Dense, well cured buds grind evenly and pack consistently, improving the overall quality of the pre roll.

- Color and Aroma: Vibrant color and strong, fresh aroma are indicators of well cultivated and properly cured cannabis.

3. Developing Strong Supplier Relationships

The reliability of a manufacturer’s raw material supply chain is just as important as the quality of the cannabis itself. Building and maintaining strong relationships with reputable suppliers ensures access to high quality material even during periods of high demand.

- Auditing Suppliers: Regular visits and audits help verify that cultivators adhere to best practices in growing, harvesting, and curing cannabis.

- Transparency and Communication: Open communication about quality expectations, such as cannabinoid percentages and terpene levels, fosters trust and alignment with suppliers.

4. The Impact of High-Quality Inputs on the Consumer Experience

Investing in premium raw materials ensures that the all pre rolled joints delivers on all fronts:

- Flavor and Aroma: Rich terpene content enhances the sensory appeal of the product.

- Functionality: Balanced moisture levels and consistent grinding ensure an even burn and optimal airflow.

- Consistency: Using high quality, uniform cannabis builds consumer trust by delivering reliable results time and time again.

Grinding and Uniform Particle Size

The grinding process is a cornerstone of crafting the perfect pre roll, directly impacting its quality, performance, and user experience. Achieving a uniform particle size during grinding is essential for several reasons:

- Too fine: Over grinding cannabis creates a powdery consistency that can restrict airflow within the pre roll. This can lead to harsher, less enjoyable hits and potential clogging during smoking.

- Too coarse: On the flip side, under grinding results in larger pieces that cause uneven combustion. This not only diminishes the smoking experience, but also leads to waste, as unburned cannabis can remain at the end of the joint.

Proper grinding ensures a balanced size that promotes optimal airflow and a consistent burn. This uniformity also supports even rolls during the manufacturing process, reducing the likelihood of uneven pre rolls or loose packing. Ultimately, a well ground blend enhances both the burn quality and the overall smoking experience, delivering a smoother and more enjoyable session for the end user.

Filling, Rolling, and Sealing Techniques

Each pre roll must maintain consistent weight and shape to ensure a professional appearance and optimal function. Modern manufacturing techniques and machinery are designed to:

- Accurately Fill Pre Rolls: This ensures uniform packing, avoiding gaps or overpacking, which allows for an even burn and smooth airflow.

- Achieve Precise Rolling: Advanced machines create a tightly packed, uniform structure for a clean, professional look.

- Perfectly Seal Pre Rolls: Seals are tight and secure, preventing spillage and preserving the potency of the cannabis.

These processes work together to ensure all pre rolled products are reliable, visually appealing, and deliver an optimal smoking experience.

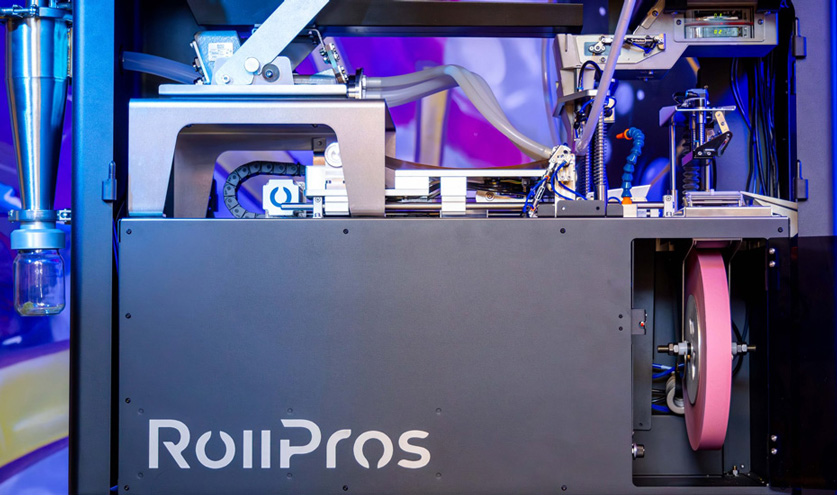

The Role of Automation in Pre-Roll Manufacturing

Automated vs. Manual Pre Roll Production

Manual pre roll production offers a personal, hands on approach that can be appealing for small batches or artisanal production. However, it often falls short when it comes to the precision, consistency, and efficiency required for larger scale operations. Manual methods can introduce variability, resulting in uneven fills, inconsistent weight, and a less polished finished product.

On the other hand, automation bridges this gap, offering a sophisticated, scalable solution that excels in high volume production while maintaining quality standards. Automated systems ensure precise, uniform fills, consistent rolling, and secure seals every time, significantly reducing the risk of human error. Automation also streamlines the process, allowing for faster production and the ability to meet growing demand without sacrificing the integrity of the pre roll. By integrating cutting edge technology, automated systems help manufacturers achieve both efficiency and reliability, ensuring that each pre rolled joint meets exacting standards of quality and consistency.

Benefits of Using Automated Pre-Roll Manufacturing Equipment

- Unmatched Consistency: Automated pre roll machines provide unparalleled uniformity in every step of the process. From precise filling to consistent weight and even rolling, these machines ensure that each pre roll is identical, reducing variability and delivering a uniform product with every batch. This consistency helps maintain a professional appearance and guarantees a smoother, more reliable smoking experience for consumers.

- Enhanced Efficiency: Automation dramatically increases production speed, allowing machines to produce thousands of pre rolls in the time it would take manual workers to complete a fraction of that amount. This not only meets high volume demand but also reduces labor costs and minimizes production time. The ability to scale up production efficiently is crucial in meeting market demands while maintaining cost effectiveness.

- Improved Quality Control: Advanced automated systems come equipped with sophisticated sensors and mechanisms designed to maintain tight tolerances throughout the entire production process. These sensors monitor key factors like fill weight, tightness, and roll quality in real time, allowing for immediate adjustments to ensure each pre roll meets precise standards. Additionally, defects such as over or under filled rolls are identified and addressed before packaging, ensuring that only top quality products reach the consumer.

Together, these benefits make automated pre roll manufacturing equipment an essential tool for producers aiming to meet high quality standards while efficiently scaling up production.

Why Automation Matters

As the cannabis industry grows, consumer expectations for quality and availability continue to rise. Automated pre roll manufacturing not only meets these expectations but also sets new benchmarks for consistency, scalability, and innovation. With cutting edge equipment, businesses can streamline their processes, reduce waste, and deliver superior products to market faster than ever before.

Key Challenges in Maintaining Consistent Quality in Pre Rolled Products

Manual pre roll production offers a personal, hands on approach that can be appealing for small batches or artisanal production. However, it often falls short when it comes to the precision, consistency, and efficiency required for larger scale operations. Manual methods can introduce variability, resulting in uneven fills, inconsistent weight, and a less polished finished product.

Variability in Material Quality

Sourcing Consistent Cannabis Strains

The quality of pre rolls starts with the cannabis itself, but fluctuations in strain availability can disrupt consistency. Environmental factors, harvest cycles, and supply chain limitations may lead to variations in cannabinoid profiles, terpene content, and moisture level.

- Solution: Establish long term partnerships with reliable cultivators who adhere to strict quality control measures. Some manufacturers are also investing in in-house cultivation to have more control over raw material quality.

Ensuring Even Moisture Content and Particle Size

Moisture content plays a pivotal role in the burn rate and overall smoking experience of pre rolls. Overly dry material burns too quickly, while excess moisture can result in harsh, uneven burn. Similarly, inconsistent particle size after grinding can affect airflow and combustion.

- Solution: Regular testing of moisture levels and using precision grinding equipment are critical steps. Implementing standardized drying and curing processes ensure optimal moisture retention.

Human Errors in Pre Roll Production

Issues Arising from Manual Production

Manual production methods introduce significant variability, including uneven filling, improper sealing, and inconsistent weights. These discrepancies not only compromise product quality but also affect customer satisfaction and brand reputation.

- Solution: Transitioning to automated systems can drastically reduce errors and enhance consistency. For companies still relying on manual methods, detailed standard operating procedures (SOPs) should be implemented.

Training Staff to Ensure Quality Control

When manual processes are unavoidable, well trained staff becomes essential to maintaining quality standards. Poorly trained workers are more likely to make mistakes, such as incorrect rolling techniques or failing to identify defective products.

- Solution: Comprehensive training programs should cover everything from basic production techniques to advanced quality control protocols. Ongoing education helps ensure staff remain knowledgeable about evolving industry standards.

Weight and Filling Consistency

Challenges in Maintaining Uniform Pre Roll Weights

A consistent pre roll weight is a hallmark of quality, ensuring a reliable and enjoyable experience for consumers. However, achieving this uniformity is particularly challenging in manual production, where even minor errors can lead to noticeable discrepancies.

- Solution: Utilize automated filling equipment to ensure accurate weight distribution. For smaller operations, periodic weight checks during production can help maintain standards.

Avoiding Overfilling or Underfilling Issues

Overfilling pre rolls can lead to tears in the paper, making the product unusable. Underfilling, on the other hand, results in a loose and satisfying smoking experience.

- Solution: Advanced filling machines equipped with sensors and weight calibration tools can prevent overfilling and underfilling. Manual processes should include visual inspections and weight verification at multiple stages of production.

Quality Assurance Measures

Consistency requires a strong quality assurance (QA) framework that spans the entire production process:

- Pre-Production QA: Testing raw materials for cannabinoid content, terpene profiles, and moisture levels.

- In-Process QA: Conducting real time checks for weight, fill density, and rolling uniformity during production.

- Post-Production QA: Inspecting final products for defects, verifying packaging integrity, and conducting consumer experience trials.

Strategies to Ensure Consistent Quality in Pre-Roll Manufacturing

Consistency is essential to success in pre roll manufacturing. By adopting a proactive and multifaceted approach, manufacturers can ensure that every pre roll meets the highest standards of quality. This involves integrating precise automation, rigorous quality control, and continuous process refinement. With this strategy, manufacturers can maintain uniformity across every product, ensuring that each pre roll delivers a reliable and premium experience for the consumer.

Implementing Rigorous Quality Control Systems

Regular Inspections During Production

Establishing a routine inspection process at various stages of production is critical for catching and addressing issues early. This proactive approach reduces waste, minimizes defects, and ensures a consistent end product.

- Key Inspection Stages

- Weight: Confirming each pre roll meets the specified weight tolerance

- Packing: Ensuring even distribution of cannabis for a smooth burn

- Sealing: Checking for secure seals to prevent spillage and preserve freshness

Automated Quality Checkpoints

Incorporating advanced manufacturing equipment with builtin quality checks can streamline the inspection process. These systems often include sensors and AI-powered algorithms that detect irregularities in real time, ensuring consistent quality at scale.

Leveraging Technology for Quality Assurance

Investing in cutting-edge pre-roll manufacturing equipment is a game-changer for maintaining consistency. Modern machines offer:

- Precision: Automated systems ensure uniform filling, rolling, and sealing with minimal variation.

- Efficiency: Faster production rates reduce bottlenecks without compromising quality.

- Data Integration: Advanced sensors collect and analyze data, providing insights to optimize production processes and preempt potential issues.

Emerging Technologies:

- Vision Systems: Detect visual imperfections such as uneven filling or improper sealing.

- Weight Verification: Inline scales monitor weight consistency in real-time.

- Smart Packaging: Incorporating QR codes or RFID technology for traceability and customer feedback integration.

Sourcing High-Quality Raw Materials

Consistency begins with reliable suppliers. Fluctuations in raw material quality can significantly impact the final product, making strong supplier relationships essential.

- Best Practices:

- Conduct regular audits of supplier facilities to verify compliance with quality standards.

- Clearly communicate expectations for cannabinoid profiles, terpene content, and moisture levels.

- Develop contingency plans to address potential supply chain disruptions.

Collaborative Partnerships:

Engage suppliers in long-term agreements that include mutual quality improvement initiatives and shared responsibility for meeting production goals.

Continuous Training and Development

Empowering the Workforce

A well-trained team is crucial for maintaining high-quality standards. Employees should be equipped with the knowledge and skills needed to operate advanced machinery and adhere to quality protocols.

- Key Training Areas:

- Proper handling of raw materials to avoid contamination.

- Operating and maintaining automated equipment.

- Identifying and troubleshooting common production issues.

Ongoing Education:

Encourage staff to stay informed about industry trends and emerging technologies through workshops, certifications, and cross-training programs. A knowledgeable workforce can adapt to changes and contribute to continuous improvement efforts.

The Role of Customer Feedback

Closing the Loop

Customer feedback is an invaluable resource for assessing product performance and identifying areas for improvement. Actively seeking and analyzing this input helps manufacturers align their processes with consumer expectations.

- Feedback Channels:

- Online reviews and surveys.

- Direct feedback through customer service interactions.

- Data from retailers and distributors.

Actionable Insights:

Use feedback to refine manufacturing processes, enhance product features, and address recurring issues. For example, if consumers report uneven burns, investigate potential causes such as particle size variation or inconsistent packing.

Achieving Excellence Through Integration

Ensuring consistent quality in pre-roll manufacturing requires a holistic approach that combines technology, supplier partnerships, workforce training, and customer-centric practices. By integrating these strategies, manufacturers can not only meet industry standards but also exceed consumer expectations, positioning themselves as leaders in a competitive market.

Conclusion

Ensuring consistent quality in pre-roll manufacturing presents both a challenge and a significant opportunity for cannabis producers to differentiate themselves in a competitive market. The process requires meticulous attention to detail, from sourcing high-quality raw materials to addressing human errors and minimizing weight inconsistencies. These challenges, however, are surmountable with the right strategies and tools.

Embracing automation and advanced manufacturing technologies is no longer optional—it’s essential. Automated systems provide the precision, scalability, and efficiency needed to maintain uniformity across large-scale operations. Coupled with rigorous quality control protocols and frequent inspections at every stage of production, manufacturers can identify and rectify potential issues before they impact the end product.

Equally important is investing in the workforce. Ongoing staff training and development empower employees to stay abreast of industry advancements, adopt best practices, and uphold stringent quality standards. This combination of technological and human expertise ensures every pre roll meets and exceeds consumer expectations.

By committing to excellence and consistency, pre roll manufacturers can build lasting trust with consumers, enhance their brand reputation, and secure their position as leaders in the growing cannabis industry. Those who prioritize quality not only meet the demands of today’s market but also set the standard for its future.