Commercial Grinders for

Pre-roll Production

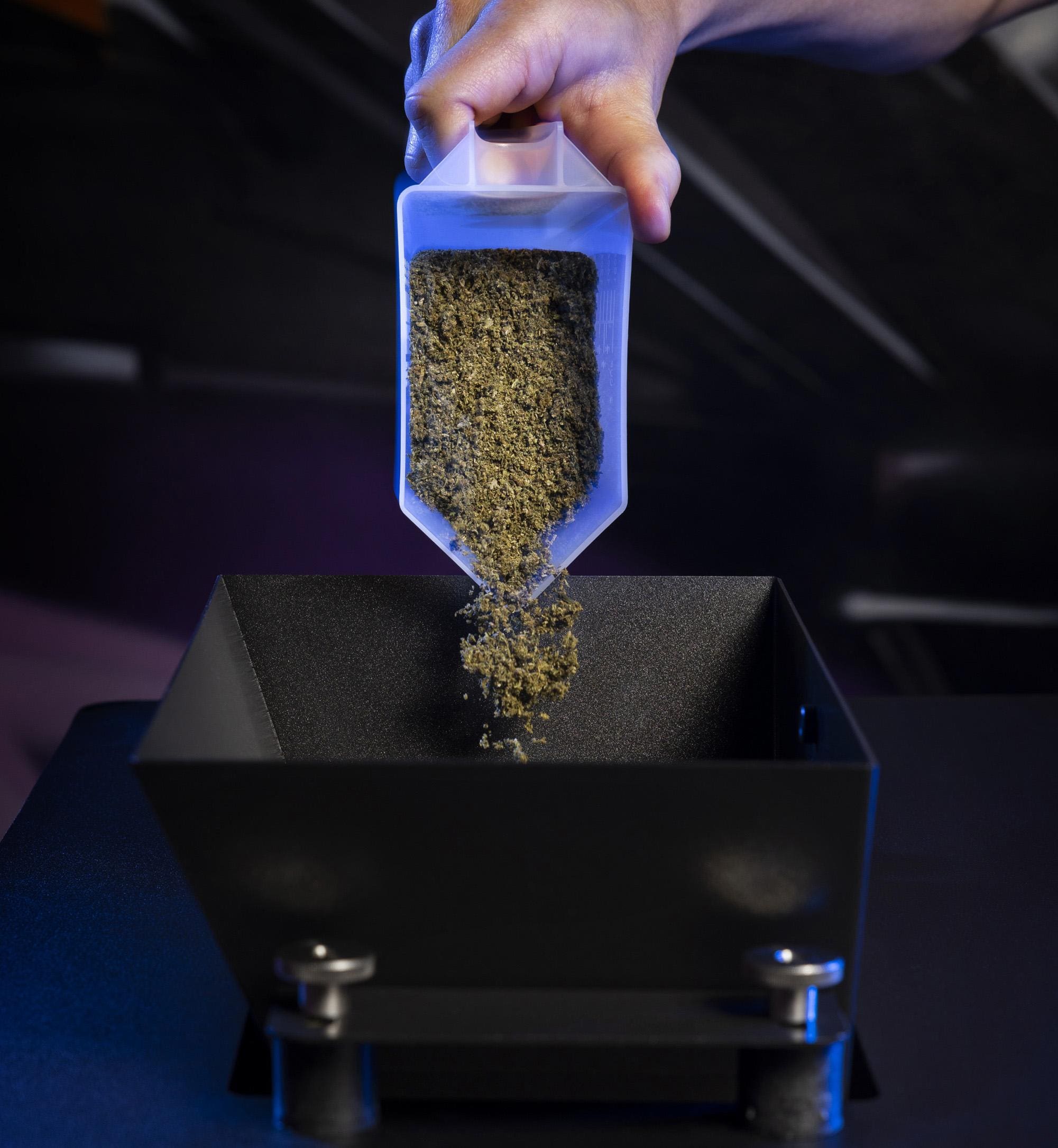

Not a small, twist-top grinder made for consumer use, but one able to break down a lot of cannabis plant material quickly.

A commercial grinder is capable of such a task—allowing operators to process large quantities of cannabis plant material fast. But commercial grinders also have powerful motors that heat up over time, and aggressive grinding exposes cannabis flower to additional heat produced by the kinetic energy created while grinding. When cannabis flower is heated above room temperature, its terpenes and cannabinoids burn off, which degrade its quality.

Some commercial grinders used in processing facilities today are common industrial-sized kitchen blenders, designed to hygienically pulverize material. While these are an effective way to grind kitchen herbs and other food products, it ruins trichome dense cannabis. The more times a blade, paddle, or whip hits the material, the greater chance of trichomes deterioration. All of which can ultimately cut into profit margins.

When grinding for pre-roll production, the goal is to break the cannabis flower up into smaller, uniform-sized particles. This allows for an even burn while supporting the structure of the pre-rolled joint, cone, or blunt. A gentle grind can also result in significant cost savings by:

Since aggressively grinding cannabis pulverizes trichomes, it also creates excess kief. And while you might be thinking that extra kief in your pre-roll will enhance the customer’s experience, in excess, it can have unintended negative effects. First off, excess kief increases the weight of your pre-rolls and heavier joints break easier. When too much powdery kief gets packed into a pre-roll, it restricts the airflow. This can cause pre-roll canoeing, where one side of it burns more than the other.

As with all equipment, industrial size grinders have been designed for many applications. Fortunately, there are commercial cannabis mills optimized to mitigate some issues with grinding flower, shake, and trim into a perfect, homogeneous blend of cannabis material—large enough to allow airflow, yet fine enough for a perfectly packed pre-roll.