Automated pre roll machines are revolutionizing the cannabis industry by streamlining the process of rolling cannabis products. These machines significantly increase efficiency, consistency, and production capacity for businesses. As the cannabis market continues to grow, automation is becoming essential to meet rising demand, reduce operational costs, and maintain high-quality standards. The integration of advanced technology not only supports operational scalability but also ensures compliance with strict regulatory standards, making automated systems an indispensable asset for cannabis producers.

Why Fully Automated Pre Roll Machines Are the Future of Cannabis Production

How Automation Boosts Efficiency, Quality, and Scalability

The Rise of Automated Pre Roll Machines

The rise of automation in cannabis production is also a response to the growing diversity in consumer preferences. As new product types emerge, manufacturers must adopt versatile solutions that can adapt to changing market demands. Automated pre roll machines address this need by offering customization options that cater to various cannabis strains, roll sizes, and packaging requirements. Furthermore, these machines enhance operational workflows, making it easier for producers to align with industry trends, such as the rise of infused pre-rolls and eco-friendly packaging.

Benefits of Fully Automated Pre Roll Machines

1. Efficiency and Speed

Automated pre roll machines drastically improve output compared to manual or semi-automated methods. By streamlining production, businesses can produce thousands of pre-rolls in a fraction of the time it takes with traditional methods. This not only boosts efficiency but also enables companies to meet high-volume orders without overburdening their workforce. For instance, high-speed pre-roll machines can produce up to 1,000 pre-rolls per hour, a rate that is impossible to achieve manually. Such efficiency ensures businesses can meet seasonal surges in demand, particularly during peak periods like holidays or product launches.

2. Consistency and Quality Control

Achieving consistent quality is critical in the cannabis industry, where consumer satisfaction and regulatory compliance go hand in hand. Automated machines ensure uniform filling, rolling, and sealing, reducing variability in product quality. Precision dosing mechanisms ensure that each pre-roll meets the required weight and potency standards, building consumer trust. Consistency is key in the cannabis world, where users seek reliable experiences and predictable effects every time, ensuring an enjoyable and satisfying session with each use. Automated quality checks further enhance reliability, reducing the likelihood of recalls due to substandard products.

3. Cost Savings

While the initial investment in automated machinery can be substantial, the long-term savings outweigh the upfront costs. Automation reduces labor expenses, minimizes material waste, and lowers the likelihood of product recalls due to quality issues. These cost efficiencies are particularly beneficial for large-scale operations seeking to improve their bottom line. Additionally, by reducing reliance on manual labor, businesses can reallocate resources to other strategic areas, such as research and development or marketing. Over time, these machines contribute to higher profit margins by enabling predictable and efficient production cycles.

4. Improved Workplace Safety

Manual rolling processes can be physically demanding and repetitive, leading to workplace injuries over time. Automation eliminates these risks by reducing the need for manual handling, thereby creating a safer work environment. Employees can focus on overseeing operations and performing higher-value tasks, leading to improved job satisfaction and reduced turnover. Moreover, the reduction in repetitive strain injuries and other workplace hazards aligns with corporate responsibility goals, contributing to a healthier and more sustainable workforce.

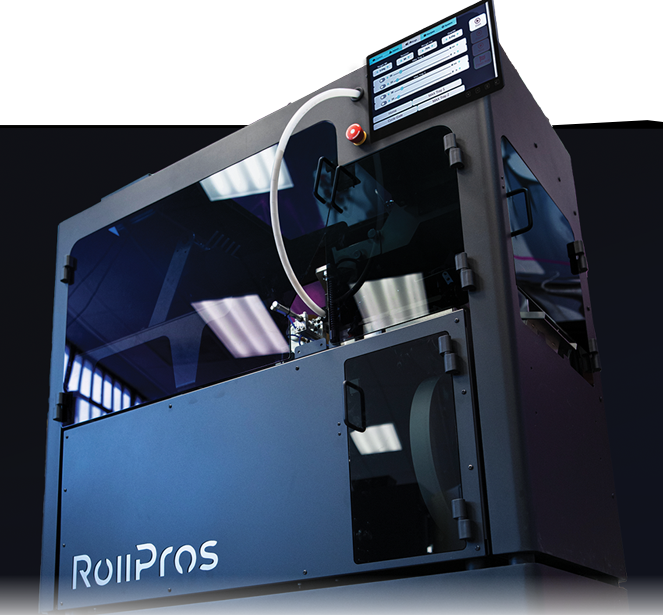

How Automated Pre Roll Machines Work

Automated pre roll machines streamline the process of filling and rolling cannabis into joints. They use precision mechanisms to evenly fill ground cannabis into cones or rolls, ensuring consistency in size and weight. These machines often feature adjustable settings for various rolling preferences and can operate at high speeds, making them ideal for large-scale production while maintaining quality and efficiency.

Technical Overview

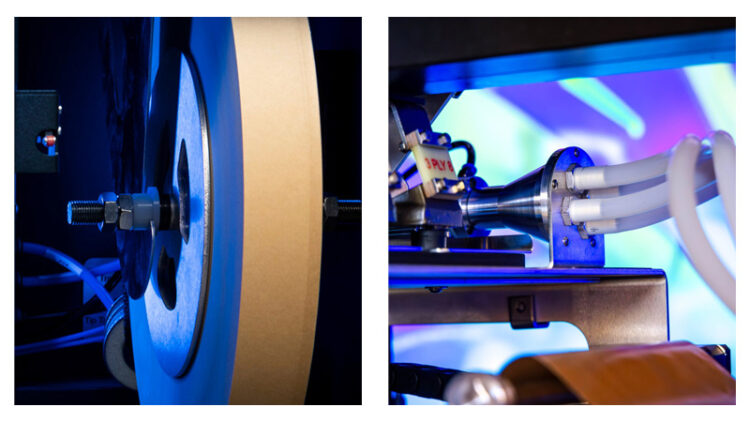

Automated pre roll machines are designed to handle every step of the production process, from filling rolls to sealing and packaging. These machines typically include:

- Filling Hoppers: Ensure precise dosing of cannabis into pre-rolls.

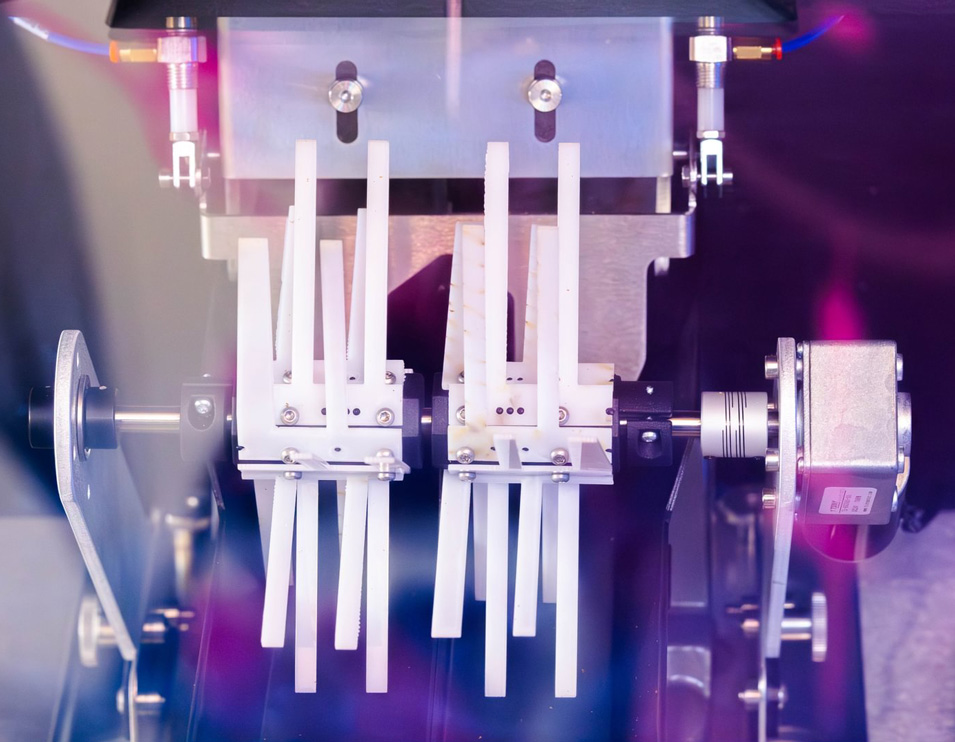

- Rolling Mechanisms: Securely roll the cannabis into a compact, even shape.

- Packaging Units: Automate the final steps of sealing and preparing pre-rolls for distribution.

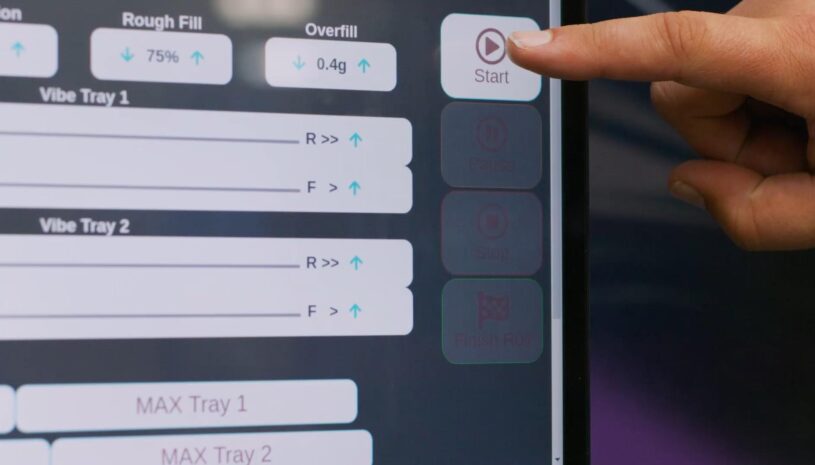

Machines can often be adjusted to accommodate different cannabis strains, grind consistencies, and roll sizes, making them versatile for various product lines. Advanced models may also include features like de-clumping mechanisms to ensure smooth filling and automated reject systems to remove defective products from the production line. Modern designs incorporate features like IoT (Internet of Things) connectivity, enabling real-time monitoring and adjustments for optimal performance.

Key Features

- High-Speed Production: Capable of producing hundreds of pre-rolls per hour, these machines cater to the growing demands of large-scale operations. High-speed production minimizes downtime and ensures businesses can keep pace with market needs. For example, during peak demand seasons or promotional campaigns, high-speed capabilities enable swift scalability, ensuring product availability without delays.

- Precision Dosing: Precision dosing mechanisms ensure consistent weight and potency in every pre-roll, eliminating inconsistencies that might arise from manual handling. This feature is particularly critical for compliance with stringent cannabis regulations and maintaining consumer trust. Advanced systems use weight sensors and automated adjustments to guarantee exact dosing, ensuring each pre-roll delivers a reliable experience.

- Reduced Labor Needs: Automation minimizes the need for manual intervention, significantly reducing human error. With fewer staff required for repetitive tasks, businesses can reallocate their workforce to focus on innovation, customer service, and strategic planning. Additionally, automation reduces labor turnover by alleviating the physical strain associated with manual pre-roll production.

- IoT Integration: IoT-enabled machines offer real-time monitoring and optimization of production workflows. Operators can access data on machine performance, production output, and maintenance needs from a centralized dashboard. This connectivity ensures that machines operate at peak efficiency, reducing downtime and allowing proactive troubleshooting.

- Customizable Settings: Automated pre roll machines feature customizable settings to accommodate different product types, such as infused pre-rolls, specialty rolls, or multi-strain blends. This flexibility enables manufacturers to diversify their product lines and cater to evolving consumer preferences. Customization also extends to packaging options, ensuring brands can differentiate their offerings in a competitive market.

Cannabis Industry Trends Driving Automation

Cannabis industry trends that are pushing the need for automation:

1. Market Growth

The global cannabis market is expanding rapidly, with increased legalization fueling demand for high-quality products. Automated pre roll machines allow businesses to scale production efficiently to meet market demands. By 2030, the cannabis market is projected to reach a valuation of over $100 billion, underscoring the need for scalable production solutions. This rapid growth highlights the importance of automated systems in meeting diverse consumer needs and staying ahead of market competition.

2. Consumer Expectations

Modern consumers expect consistent quality and reliable dosing in cannabis products. Automation ensures uniformity, enhancing brand reputation and customer satisfaction. The growing popularity of premium pre-rolls and infused products further highlights the importance of precise manufacturing processes. Additionally, the increasing focus on sustainability has led to a demand for eco-friendly packaging and production practices, both of which are facilitated by automation.

3. Regulatory Compliance

Strict regulations around dosing accuracy and product labeling make automation a valuable tool for compliance. Automated machines help producers maintain precise control over product specifications, reducing the risk of regulatory violations and associated fines. By integrating data tracking systems, producers can also ensure traceability, a key requirement in many jurisdictions.

4. Sustainability

As sustainability becomes a priority, automation helps reduce waste and energy consumption. By optimizing material usage and minimizing errors, businesses can improve their environmental footprint. Many automated systems also feature energy-efficient designs and recyclable packaging options, aligning with eco-conscious consumer preferences. Furthermore, the reduction in defective products and waste contributes to overall cost savings and environmental responsibility.

Challenges and Considerations

While the benefits of automation are clear, businesses must also consider potential challenges, such as:

- Initial Investment: High upfront costs can be a barrier for smaller businesses.

- Training Requirements: Employees need to be trained to operate and maintain automated systems.

- Technology Integration: Ensuring compatibility with existing workflows and systems can be complex.

By addressing these challenges through strategic planning and gradual implementation, businesses can maximize the benefits of automation while minimizing disruptions. Partnering with reliable equipment providers and investing in employee training can significantly ease the transition.

Why Cannabis Businesses Should Invest in Automated Pre Roll Machines

The decision to invest in automated pre roll machines is a strategic one that offers numerous benefits:

- Competitive Edge: Businesses gain a substantial advantage by boosting efficiency, ensuring product consistency, and delivering a superior product that stands out in a competitive market.

- Faster Production: Automation accelerates production, enabling rapid scaling and efficient operations to meet growing market demand while maintaining quality and reducing downtime.

- Cost Savings: By minimizing labor costs and reducing material waste, automated systems offer significant financial savings, improving profit margins and enabling reinvestment in other areas of the business.

- Regulatory Compliance: Automated machines ensure precise dosing and enhanced traceability, helping businesses stay compliant with ever-evolving industry regulations and maintaining product integrity.

- Sustainability: Eco-friendly production processes align with consumer preferences for sustainable practices, reducing environmental impact and supporting long-term business sustainability goals.

Conclusion

Automated pre roll machines represent the future of cannabis production, offering unparalleled efficiency, consistency, and scalability. As the industry continues to evolve, automation will play an increasingly vital role in meeting consumer expectations and regulatory standards. By investing in automated cannabis manufacturing equipment, businesses can position themselves for long-term success, leveraging technology to drive innovation, reduce costs, and enhance product quality. In a rapidly growing market, embracing automation is not just an option—it’s a necessity for staying competitive and sustainable.