At RollPros, we proudly manufacture the Blackbird, which we still believe remains the best automated pre roll machine in the cannabis industry today. We’re so confident in our machine that we always encourage operators to research the full market before making a decision. The right choice depends on your goals, workflow, and production scale.

2025: Best Automated Pre-Roll Machines

This updated guide takes a closer look at the leading automated pre roll machines of 2025. You will find key details on performance, best-fit use cases, pricing estimates, and what sets each manufacturer apart.

Note: Pricing information below is solely based on public information and estimations. You should contact each company for accurate quotes

What to look for in an automated pre roll machine

Automated pre roll machines have come a long way in the past few years. Modern systems are faster, more reliable, and built to reduce labor without sacrificing quality. When evaluating your options, consider the following features:

- Production Speed: Throughput is critical for staying competitive. High-capacity machines can produce thousands of joints per hour while maintaining consistent quality.

- Automation Level: Some models still require manual steps, while fully automated systems handle everything from weighing and filling to closing and packaging. It truly depends on how hands-on or hands-off you want to be with your process.

- Customizability: The ability to fine-tune joint size, fill weight, and density allows brands to craft unique products that stand out on retail shelves. Many machines also offer options to customize paper type, crutch material, and even color for a fully branded experience.

- Ease of Maintenance: Modular design, quick part access, and strong technical support reduce downtime and make ongoing maintenance more manageable.

- Smart Technology: IoT technology and data analytics help operators monitor performance in real time, identify trends, and uncover ways to improve efficiency and yield.

- COGS: The cost of goods per joint is not identical across the board. Don’t just consider the overall price of the machine, consider the COGS and labor costs to operate it.

- Support: Commercial-scale equipment is only as good as the training and support that comes with it. Ask around and see what existing customers say about their support experience. And don’t be afraid to ask to speak to a company’s support team BEFORE you purchase. If they say no, that’s a red flag.

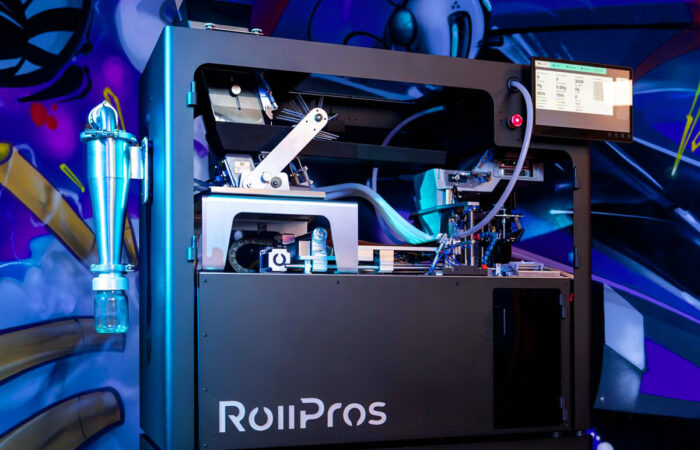

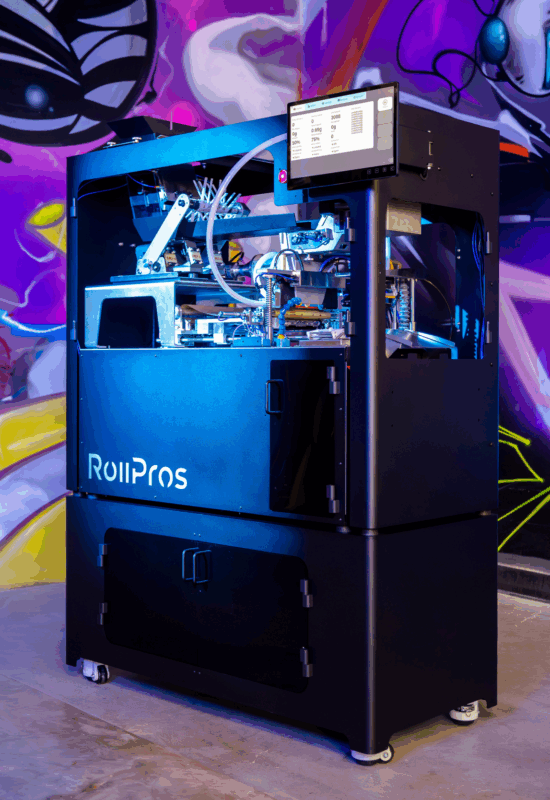

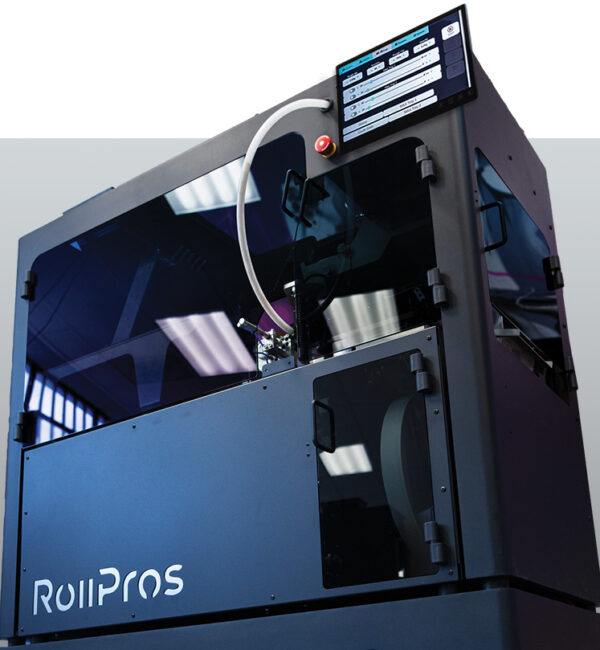

RollPros Blackbird

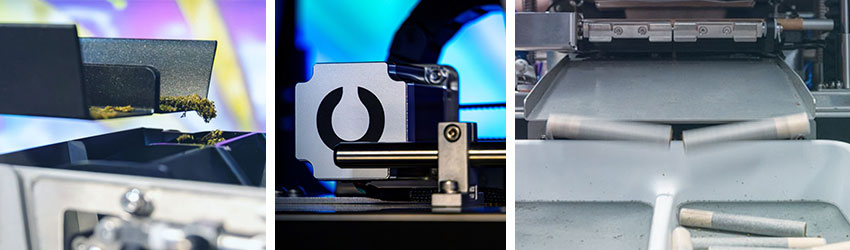

The Blackbird remains THE most advanced automated pre roll machines available today. It is still the only commercial-scale system that actually rolls joints instead of filling pre-formed cones. This creates a finished product with the same airflow, structure, and burn quality as a hand-rolled joint.

The Blackbird also allows producers to use a wider range of flower textures and moisture levels, reducing material waste and increasing flexibility. Because it rolls from paper rather than cones, it achieves an impressively low cost per joint of around $0.03. More than 200 units are currently operating across the US and Canada, collectively producing over 140 million joints, supported by RollPros’ industry-leading training and lifetime support. (Current run-rate is 1.3-1.5 million joints per week.) Want to see the Blackbird run live?

Best For: Businesses and operators focused on premium quality, consistency, and scalability.

Notable Users: Jungle Boys, Seed Junky, Benson Arbor, Grasshopper Farms, Raw Gardens, Cresco, Phat Panda, Hamilton Farms

Price Range: Contact us for an accurate quote

PreRoll-er

Procepack’s Preroll-Er machines are widely recognized for their durability. The company, based in Quebec, has a long history in automation for other industries like beauty, coffee, and craft beer, and brings that expertise into the cannabis space. Their pre roll lineup includes smaller centrifugal units and larger cone-filling models that rely on tamping to fill joints. The company also offers packaging, cart-filling, and labeling machines, giving producers a complete production ecosystem.

Best For: Canadian producers or operations looking for full production-line automation.

Notable Users: Garden Remedies

Estimated Price Range: $275,000–$325,000 for the PreRoll-Er 200

Actionpac

ActionPac takes a semi-automated approach that combines three machines working together. The system weighs out the flower, drops it into cones, and uses vibration and tamping tools to compact the material. Operators then transfer the filled cones to the “Twistmaster” for final closure. It is a batch-based process rather than a continuous system, which makes it ideal for smaller producers entering automation for the first time.

Best For: Entry-level automation or boutique pre roll brands scaling up.

Notable Users: Verano

Estimated Price Range: $100,000–$140,000 for complete setup

Hefestus

Hefestus is known for its innovative engineering and unique finishing system. They offer two different machines, The AuraOne and AuraX. According to their website, the AuraOne is intended for small to mid size operators while the AuraX is for larger ones. They have a slightly smaller footprint than some other cone-based machines. Their unique thing is that instead of twisting the tops of pre-rolls, Hefestus machines use a folded “Dutch Crown” finish that creates a clean, signature look.

Best For: Brands focused on utilizing the closure method to differentiate their products

Notable Users: King’s Garden

Estimated Price Range: $185,000 for the AuraOne and $230,000–$260,000 for the AuraX

Futurola Kockbox 500

Futurola has been around since the 90s and has a range of knockbox-style pre-roll machines. The Futurola Knockbox 500 remains one of the most accessible automated pre roll machines for small operations. It is a semi-automated, batch-based system that uses vibration to fill cones efficiently. While it lacks the automation level of larger machines, it remains an entry point for new producers who want to introduce pre-rolls without major capital investment.

Best For: Small businesses or new operators testing pre roll production.

Notable Users: Tyson 2.0

Estimated Price Range: $25,000

Accelerant

Accelerant has taken a different approach to automation with its PRO (Pre Roll Operator) series, which includes the PRO2 and PRO4 models. These machines feature optional kief coating capabilities and are offered through a usage-based model rather than traditional purchase. Producers do not own the machine but pay per pre-roll produced, with minimum monthly volumes between 120,000 and 150,000 units. It is important to keep in mind that the minimums equate to a monthly payment that is oftentimes more than you could pay per month when financing machines with some of their competitors.

Best For: High-volume producers who prefer flexible payment models over upfront capital spending.

Notable Users: Ilera Holistic

Estimated Price Range: Based on production volume and agreement terms

Apehex

The Apehex, designed by Perfectionist Rolling Equipment, continues to gain attention for its compact footprint. The six square foot machine includes a grinder and a wholesale cone account with HBI, making it a convenient all in one system for small to medium producers. According to the company, Apehex machines have produced more than 60 million pre-rolls since their launch in 2021.

Best For: Compact facilities and operators looking for streamlined automation.

Notable Users: Not publicly listed

Estimated Price Range: Not disclosed

Emerging Trends In Pre-Roll Automation

Technology continues to redefine what is possible with automated pre roll machines. In 2025, the most advanced models are smarter, more sustainable, and built for seamless integration across production lines.

Key trends include:

- AI and Machine Learning: Systems that automatically correct fill inconsistencies and maintain uniform density.

- Integrated Quality Control: Real-time sensors that detect errors or weight deviations.

- Eco-Conscious Design: Machines built to minimize waste and support recyclable materials.

- End-to-End Automation: Equipment that connects directly to packaging systems for smoother workflows and less manual labor.

These developments are helping producers scale faster, cut costs, and deliver higher-quality products to market.

Conclusion

The automated pre roll machines of 2025 continue to raise the standard for precision, speed, and consistency. Whether you are a craft producer refining your process or a large operation scaling nationwide, there is now an automation solution to fit your needs.

The Blackbird remains the only system that truly rolls joints from paper rolls at a commercial scale, delivering a truly high-quality smoking experience and unmatched production costs. As new technology and competitors emerge, one thing is clear: automation has become an essential part of building a successful and profitable pre roll business.

FAQ

What is the best pre-roll machine for 2025?

The best pre-roll machine depends on your production needs. In 2025, the top models combine speed, automation, and customizability. RollPros offers industry-leading solutions built for efficiency and scalability.

How fast can an automatic pre roll machine produce joints?

Modern automatic pre roll machines can produce thousands of joints per hour while maintaining consistency. High production speed is critical for commercial operations aiming to scale efficiently.

What’s the difference between semi-automated and fully automated pre roll machines?

Fully automated pre roll machines handle the entire process with minimal human input using AI, robotics, and sensors. Semi-automated machines still require manual steps. In 2025, fully automated systems are the preferred choice for maximum efficiency.

Are commercial pre-roll machines worth the investment?

Commercial pre-roll machines are essential for businesses that want to scale. They lower labor costs, increase production capacity, and ensure consistent product quality.

How do I maintain my automated pre roll machine?

Automated pre roll machines are easier to maintain thanks to modular design, IoT monitoring, and remote diagnostics. Follow manufacturer guidelines and schedule routine service for peak performance.