The pre-roll category is experiencing explosive growth. What was once an afterthought in dispensary offerings has quickly become one of the most in demand product segments in cannabis. Consumers crave convenience. Retailers appreciate the strong profit margins. And brands are moving fast to claim their place in this competitive space.

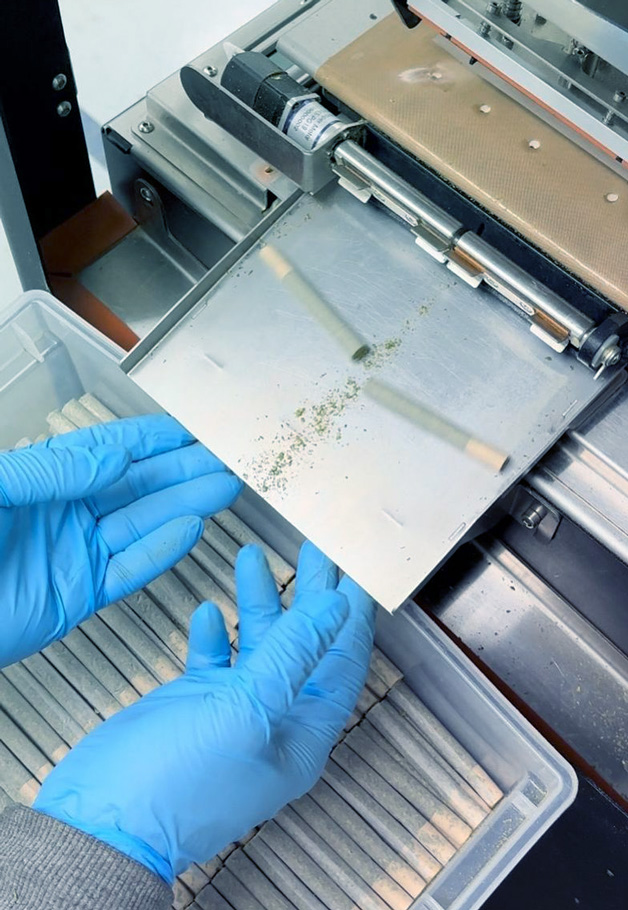

To meet that demand while maintaining consistency and efficiency, operators are investing in commercial pre-roll machines. These machines offer the precision, speed, and scalability that manual labor simply cannot achieve. But purchasing equipment is only part of the equation. Without the right strategy, workflow, and preparation, launching a pre-roll operation can lead to serious challenges. From wasted product and labor inefficiencies to poor burn quality and compliance issues, the risks are real and expensive.