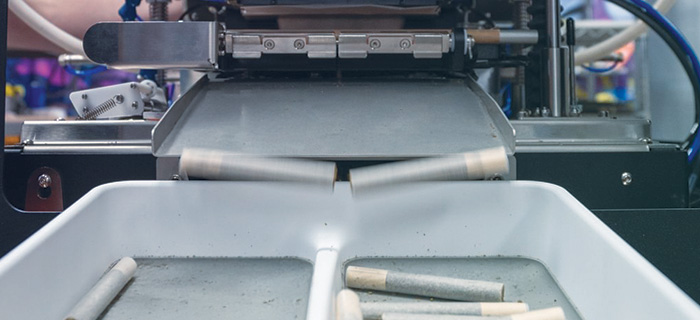

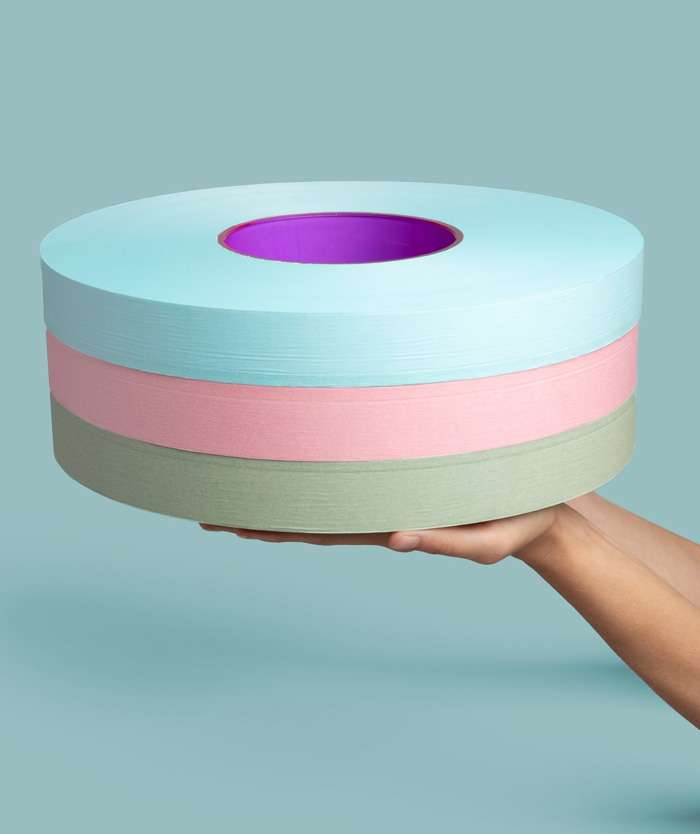

The cannabis industry is evolving rapidly, with increasing consumer demand and tighter regulations driving businesses to refine their operations. For companies producing pre rolls, efficiency, consistency, and quality are essential to staying competitive in this growing market. Traditional hand rolling methods often struggle to keep up with large scale demand and can lead to inconsistencies in weight, density, and overall product excellence.

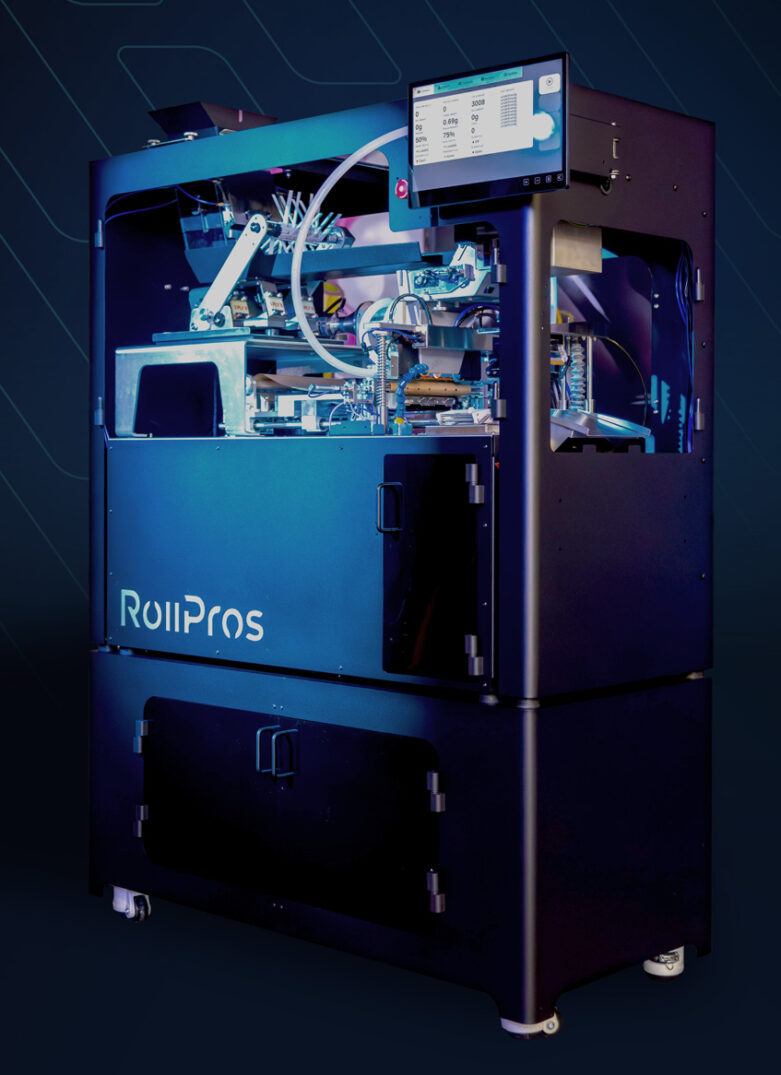

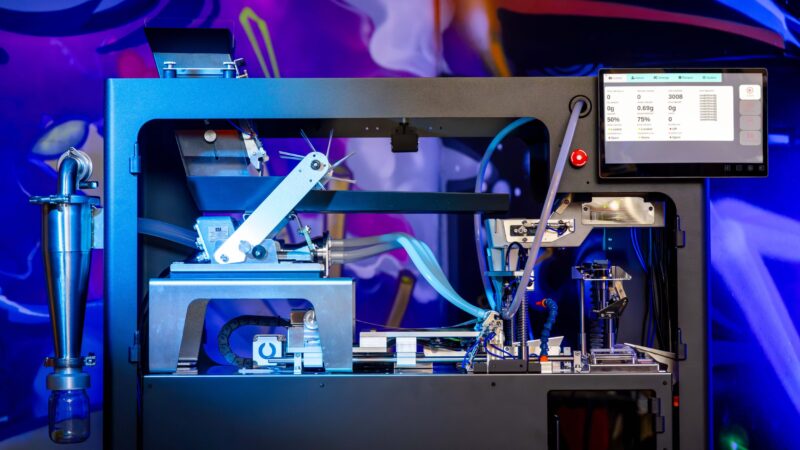

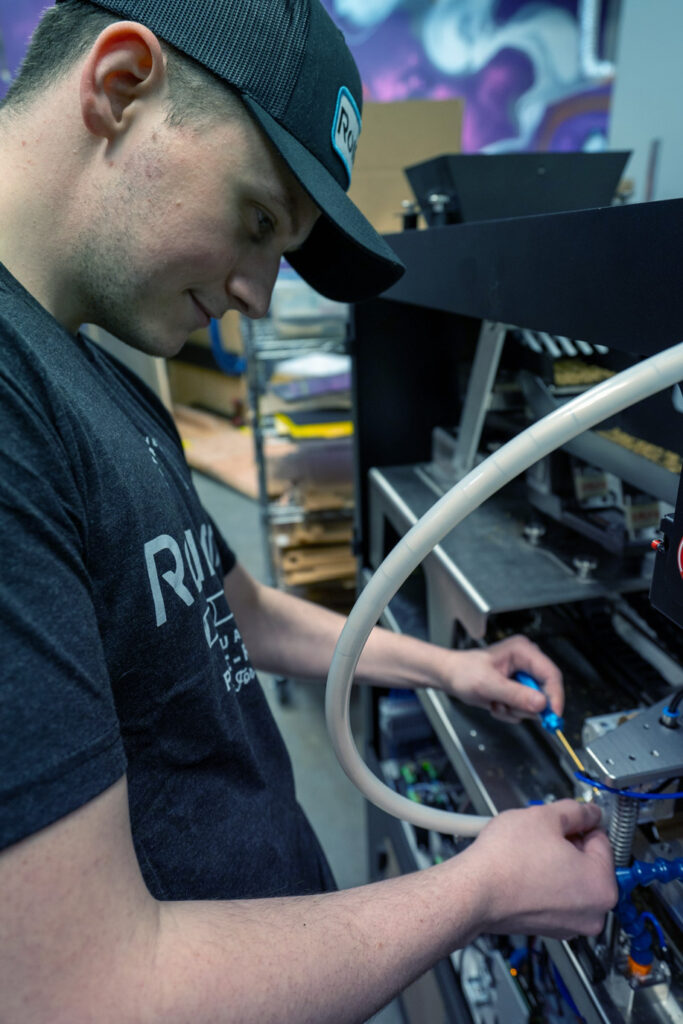

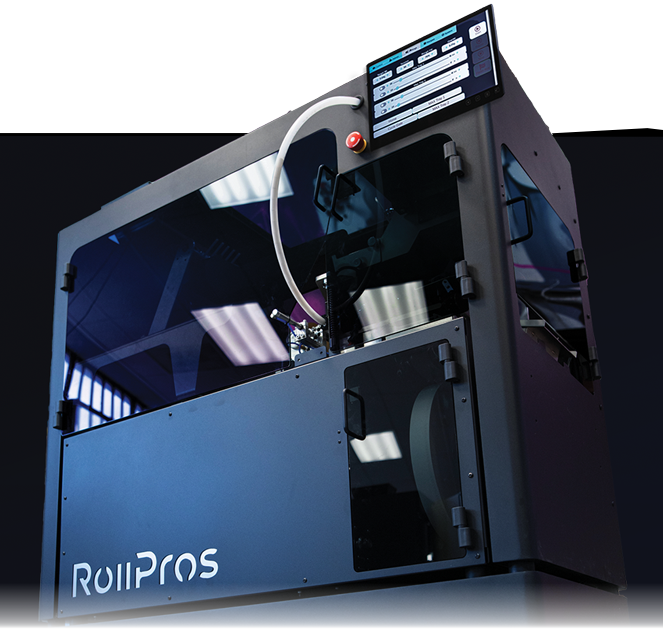

This is where automatic pre roll machines come into play. These machines have become indispensable tools for cannabis businesses, offering streamlined production, improved accuracy, and significant labor cost savings. However, not all joint rolling machines are created equal; factors such as flower quality, machine capacity, rolling technique, and overall ease of use can significantly impact the final product.

Selecting the right pre roll machine is a critical investment that can influence your brand’s reputation, customer satisfaction, and bottom line. Whether you’re a boutique craft cannabis producer or a high volume operation, understanding the key features and capabilities of different machines will help you make an informed decision. We’ll walk you through the essential factors to consider when choosing the best joint rolling machine for your business, ensuring that you achieve both efficiency and excellence in your pre roll production.